Quantitative Influences of Successive Reuse on Thermal Decomposition, Molecular Evolution and Elemental Composition of Polyamide 12 Residues in Selective Laser Sintering

Abstract

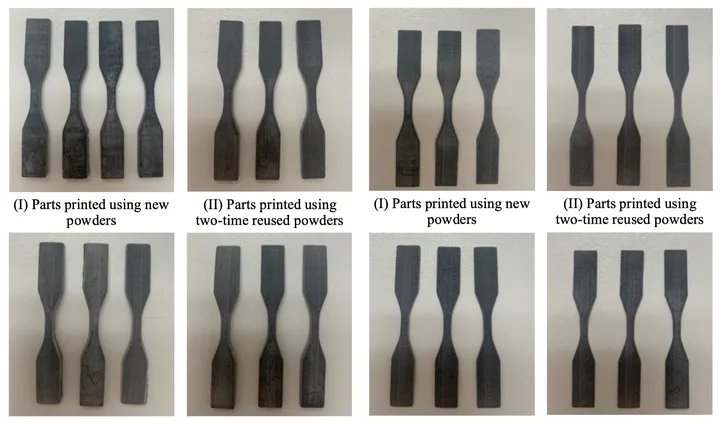

Since its addition to additive manufacturing (AM), polyamide 12 has dominated the selective laser sintering (SLS) market thanks to its stable thermal property and high mechanical quality. However, substantial un-sintered residue powders lead to economic losses and are burdensome to the environment. Though several works have reported the aging mechanism and reusability of the polyamide 12 residues in SLS, the quantitative degradation and decomposition changes of differently reused polyamide 12 are not available. This work experiments successive reuse of polyamide 12 residues and monitors quantitatively the thermal decomposition, molecular evolution, and compositional changes of the material in SLS AM. To understand the characteristics of such changes, we reused the same bucket of polyamide 12 powders up to 8 times, collected powder samples, and printed 3- and 32-layer part samples. With successive reusing, the decreased basic flowability energies per reuse calculated from 2-, 5-, and 8-time reused powders are $9.90$, $15.59$, and $12.74$ mJ, respectively. These values are important to control the flowability of polyamide 12. Laser and heat lower the material onset decomposition temperatures with reuse, making the material more labile at a decreased temperature. On the other hand, the nitrogen atmosphere delays the onset of thermal decomposition to a higher temperature. The 1 H NMR spectra reveal the degradation of polyamide 12 with reuse: in polyamide 12 parts 3D-printed using 8-time reused powders, the relative area of the peak on C-H bonds adjacent to nitrogen has a $50$ percent reduction compared to parts using new powders. The carbon deposit and degradation raise the atomic percentages of C and O by $72.49$ percent and $7.13$ percent, respectively, from new powders to the part printed using 8-time reused powders. The study newly reveals the surface carbon deposit of polyamide 12 during successive reuse of SLS. It indicates that apart from high temperature, laser is the other factor to induce polymer decomposition.

Type

Publication

International Journal of Advanced Manufacturing Technology