Robotic Inspection of Complex Metalic Parts

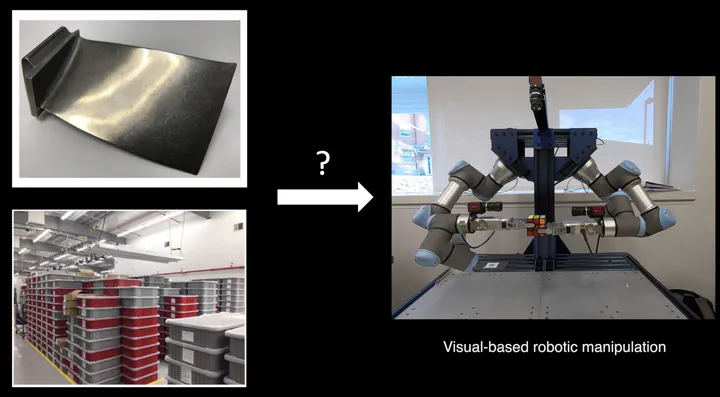

In the $72-billion (in 2020 dollar) aerospace engine industry, overlooking defects as minor as scratches and pits could lead to imbalances in air flow and part fatigue, and as a result, premature engine wear and even engine failures. Current inspections limit the manufacturing process flow: not only is inspecting complex shiny surfaces tiring and time-consuming, but the inspection process is also burdensome, subjective, and requires years of training, particularly for high-volume production with outputs of 500+ parts per day per site. Integrating lighting physics, controlled environment data collection, and machine learning, we are building a high-quality, consistent surface profiling and fault identification to continuously improve inspection performance using accumulating data. Initial results have already achieved a first-of-its-kind closed-loop imaging and 95 percent correct machine classification of the challenging defects.

Our project has been highlighted by the Advanced Robotics for Manufacturing Institute (ARM), a Manufacturing USA institute. Beyond research, our lab also brought together Boeing, UW scholars, regional Manufacturing Extension Partnerships (MEPs) in Oregon and Montana, and a small business, integrating expertise to help build a national robotic resource map for manufacturing.