New Hammerstein Modeling and Analysis for Controlling Melt Pool Width in Powder Bed Fusion Additive Manufacturing

Abstract

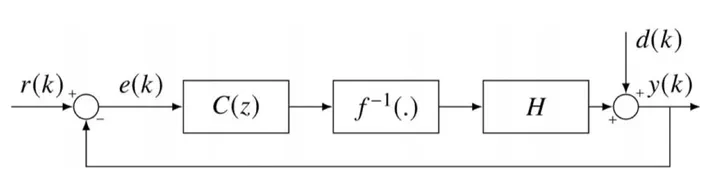

Despite the advantages and emerging applications, broader adoption of powder bed fusion (PBF) additive manufacturing is challenged by insuf fi cient reliability and in-process variations. Finite element modeling and control-oriented modeling have been shown to be effective for predicting and engineering part qualities in PBF. This paper fi rst builds a fi nite element model (FEM) of the thermal fi elds to look into the convoluted thermal interactions during the PBF process. Using the FEM data, we identify a novel surrogate system model from the laser power to the melt pool width. Linking a linear model with a memoryless nonlinear submodel, we develop a physics-based Hammerstein model that captures the complex spatiotemporal thermomechanical dynamics. We verify the accuracy of the Hammerstein model using the FEM and prove that the linearized model is only a representation of the Hammerstein model around the equilibrium point. Along the way, we conduct the stability and robustness analyses and formalize the Hammerstein model to facilitate the subsequent control designs.

Type

Publication

ASME Letters in Dynamic Systems and Control