Sustainable Additive Manufacturing

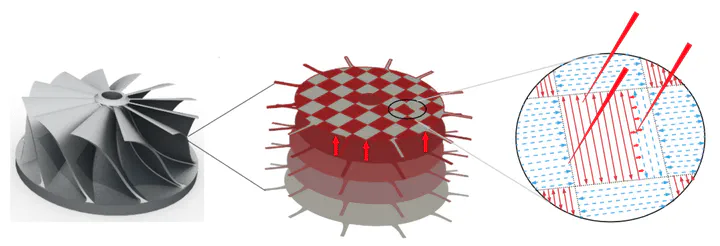

Sustainable mass customization calls for additive manufacturing procedures that understand and tolerate in-process disturbances arising from convoluted thermal cycles and varying feedstock properties when using recycled materials. This project seeks a robust selective laser sintering powder bed fusion additive manufacturing procedure to fill this critical gap. By multi-physics modeling, unique in-situ monitoring of the heat-affected-zone (HAZ), and system-theoretical analysis of the dynamic process, this project has revealed the effects of material aging on key material behaviors and final part quality. Theoretical and experimental verification elucidate how to maximize material usage and to assure sintering performance when using reclaimed Nylon and PEEK materials.

See below our publications towards a zero-waste agile manufacturing of quality-assured, short-run products.