UNIVERSITY of WASHINGTON | BOTHELL

Electrical Engineering | Science & Technology

|

|

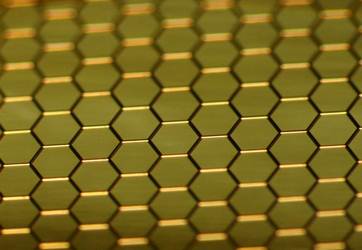

ITO-free Large-area Flexible Organic Solar Cells with an Embedded Metal Grid Roll-to-roll process has been widely used in the printing industry at high process speeds and recently adopted by organic solar cell manufacturers to demonstrate flexible, large-area, low-cost organic solar modules. The so-called stripe geometry is widely used in roll-to-roll process in order to minimize the resistive power loss in large-area solar modules. However, it has its limitations since the area used by the cell-to-cell connections reduces the overall active area of the module, leading to a significant reduction of the power conversion efficiency in modules compared to small-area cells. Recently, we demonstrated improved performance for large-area organic solar cells and modules by integrating metal grids directly with transparent electrodes. However, we found that it was difficult to coat the solution-based organic materials uniformly on top of the substrate due to the thick metal grids.

|

|

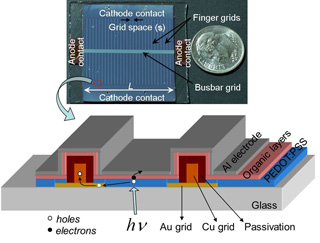

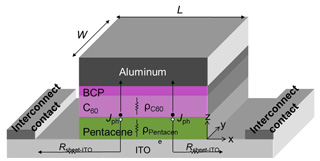

ITO-free large-area organic solar cells Low cost and high flexibility are two key features that organic electronics can offer. At the moment, indium-tin-oxide (ITO) is the most widely used transparent electrode for both organic photovoltaics (OPVs) and organic light-emitting diodes (OLEDs) since ITO has relatively high conductance compared to most other electrodes with high optical transmittance in the visible part of the spectrum. However, the high demand for indium in devices such as liquid-crystal panels and touch-screen displays has created strong price volatility for indium and has generated supply concerns. The latter is a consequence of its mining which is associated with that of zinc, making its supply dependent on the demand for zinc. These factors are driving the development of ITO substitutes for organic photovoltaic technologies. Furthermore, ITO has poor mechanical properties when deposited on flexible substrates as it is susceptible to cracks when the substrates are bent below a critical bending radius of 8 mm, thus preventing the realization of high flexibility. Hence, developing an OPV architecture in which ITO is replaced with a transparent, low-cost, and crack-tolerant electrode is of great interest. In summary, we demonstrated that an electrode that combines a metal grid and a highly conductive grade of PEDOT:PSS (Clevios PH 1000, H. C. Starck) could be used as a substitute for the conventional ITO-coated substrates. Large-area (7.3 cm2), ITO-free organic solar cells comprised of pentacene/C60 bilayer heterojunctions yielded power conversion efficiencies of 0.7%. These values have to be compared with 0.8%, the power conversion efficiency measured in devices of similar area with ITO-coated glass electrodes. While PEDOT:PSS exhibits a slightly lower optical transmittance compared with ITO, the overall reduction in photocurrent over the spectral interval [300-800 nm] is estimated to be only 8%. The light shadowing losses introduced by the metal grid are 5.5% which translates into an overall loss of 13% when scaling from small-area ITO-based devices to large-area ITO-free solar cells. Future studies will focus on the fabrication of polymer-based devices on flexible substrates, on their stability, and on their mechanical properties under flexing. The efficiencies obtained in this study with the model devices based on bilayers of pentacene and C60 are relatively modest compared to the efficiency of 8.13 % achieved recently by Solarmer Energy Inc. and certified by NREL. However, power loss density calculations show that the ITO-free device geometry described in this study with electrodes that have a rather high sheet resistance (98.4 W/sq) can be easily transposed to record high efficient cells by adjusting the thick metal grid electrode geometry. Organic photovoltaic cells have not yet reached efficiencies and lifetimes comparable to conventional crystalline silicon cells but continuous advances in material and device geometries bring them a few steps closer to commercialization. |

|

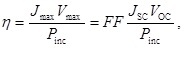

Area-scaling of organic solar cells Organic photovoltaics have received great interest in recent years due to the promising potential for the development of large-area, low-cost, light-weight solar modules with highly flexible form factors. Significant efforts have been focused on improving the power conversion efficiency through the synthesis of new light-harvesting molecules and polymers and through tandem cell architectures. The power conversion efficiency is defined by: This work report on the performance of organic solar cells based on pentacene / C60 heterojunctions as a function of active area. Devices with areas of 0.13 cm2 and 7 cm2 were fabricated on indium-tin-oxide (ITO) coated glass. Degradation of the performance with increased area is observed and analyzed in terms of the power loss density concept. The various power loss contributions to the total series resistance are measured independently and compared to the values of the series resistance extracted from the current-voltage characteristics using a Shockley equivalent circuit model. The limited sheet resistance of ITO is found to be one of the major limiting factors when the area of the cell is increased. To reduce the effects of series resistance, thick, electroplated, metal grid electrodes were integrated with ITO in large-area cells. The metal grids were fabricated directly onto ITO and passivated with an insulator to prevent electrical shorts during the deposition of the top Al electrode. By integrating metal grids onto ITO, the series resistance could be reduced significantly yielding improved performance. Design guidelines for metal grids are described and trade-offs are discussed.

|

Email: schoi [at] uwb.edu