UNIVERSITY of WASHINGTON | BOTHELL

Electrical Engineering | Science & Technology

|

|

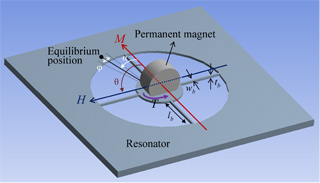

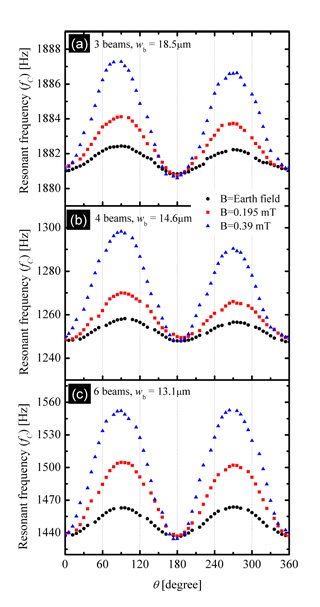

Nonlinear sensitivity enhancement of resonant microsensors and its application to low power magnetic sensing Nonlinearities in resonating structures can be used to increase the sensitivity of sensors based on these structures. An example system, a torsional resonant magnetic sensor, is analyzed to illustrate the effect. The system is composed of a disc type silicon resonator combined with a permanent magnet supported by multiple micromachined silicon beams, excitation and sensing coils, and a magnetic feedback loop. Nonlinearity effects on sensitivity have been characterized as a function of beam width and the number of beams using analytical models as well as numerical analysis. By increasing the number of beams while reducing beam width (and thereby maintaining constant nominal linear resonant frequency), large nonlinearity has been obtained, resulting in increased change in operating resonant frequency per unit applied magnetic field. The interaction between an external magnetic field surrounding the sensor and the permanent magnet generates a rotating torque on the silicon resonator disc, changing the effective stiffness of the beams and therefore the resonant frequency of the sensor. By monitoring shifts of the resonant frequency while changing the orientation of the sensor with respect to the external magnetic field, the direction of the external magnetic field can be determined. Self-resonance based electromagnetic excitation of the mechanical resonator enables it to operate with very low power consumption and low excitation voltage. A total system power consumption of less than 140 mW and a resonator actuation voltage of 1.4mVrms from a ±1.2V power supply have been demonstrated with a sensitivity of 0.28 Hz/rotational degree to the Earth’s magnetic field.

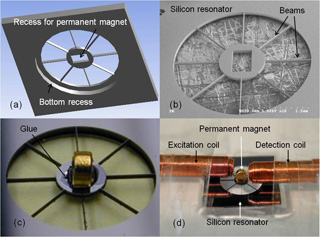

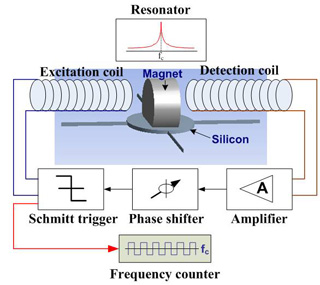

A Magnetically excited and sensed MEMS-Based Resonant Compass System A very low power consuming MEMS-based compass system is designed, fabricated, simulated, and measured. A positive feedback loop is implemented along with excitation and sensing coils to form a complete measurement system. A sensitivity of the 0.11 Hz/degree for the earth’s magnetic field is achieved while consuming 138 μW for the total system and 9.64 μW and 4mVpp for the excitation at the ±1.2 V power supply voltage. In this work, we developed an all-magnetic MEMS-based resonant compass, driven and sensed electromagnetically by an excitation and sensing coils. A simple and CMOS compatible fabrication is developed which is suitable for the further integration with other electronic components. The resonator with electromagnetic sensing and excitation coils are embedded in an amplifying feedback loop providing a stable oscillation at its resonance frequency. The magnetic amplification provided by the resonator makes it potentially suitable for compact, low voltage portable navigation systems. A number of magnetic sensors, such as flux gate magnetometers, AMR sensors and Hall-effect devices, have been reported to be sufficiently sensitive to the Earth’s magnetic field for use in this application. However, the power requirement of these devices is typically prohibitive for a long-term, portable application. Earlier, we reported an epoxy-based micromachined resonant magnetic sensor. It exhibited very low power consumption for the driving with sensitivity high enough for measuring the earth’s magnetic field. However, a relatively high operating voltage and epoxy based substrate make it incompatible with CMOS fabrication. Recently we reported a silicon-based resonant magnetic sensor incorporating excitation coil and detection Hall effect sensor. It exhibited very low driving voltage. However, it requires relatively high power consumption due to the Hall effect sensor used as a detection element. The structure consists of a permanent magnet torsionally supported on a resonant MEMS disc. The interaction between an external magnetic field H such as the Earth's magnetic field and the magnetization of the permanent magnet M generates a torque which changes the stiffness of the beam, resulting in a change of the resonant frequency of the sensor. By monitoring the changes of the resonant frequency while changing the orientation of the sensor with respect to the external magnetic field H, the direction of the external magnetic field can be determined as a function of the resonant frequency. The FEM simulation ensures the laterally torsoional movement as the primary resonant mode. The Fabricated device has 4 beams with 17 μm in beam width, 2 mm in beam length, 110 μm in beam thickness. The fabrication is based on a two-mask, single wafer silicon bulk micromachining process. A recess is etched into the bottom side silicon wafer using inductively coupled plasma (ICP) etching to reduce the thickness of the resonator structure. The top side silicon wafer is etched by ICP to realize a movable resonant disc structure (containing a recess for a permanent magnet), support beams. The permanent magnet is adhered to the center of the moving disc. The excitation and sensing coils are assembled and connected to the positive feedback circuitry loop. The circuitry consists of one 4-channel low power OP amp (OP490) along with several resistors and capacitors to perform an amplification, phase shift, and Schmitt trigger.

|

|

Email: schoi [at] uwb.edu