UNIVERSITY of WASHINGTON | BOTHELL

Electrical Engineering | Science & Technology

|

|

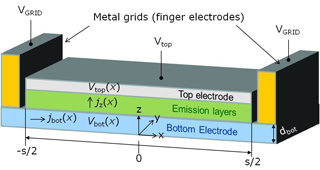

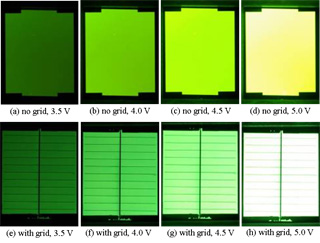

ITO-free large-area organic light-emitting diodes with an integrated metal grid Organic light-emitting diodes (OLEDs) have been extensively studied in recent years due to their potential for the development of low-cost, bright and light-weight display panels, and for lighting applications with highly flexible form factors. Significant efforts have been focused on improving the power efficiency through the synthesis of new light-emitting molecules and polymers, and through novel light extracting architectures. Although indium-tin-oxide (ITO) is the most widely used transparent electrode for both OLEDs and organic photovoltaics (OPVs), there is a great interest to find low-cost alternatives because its use in devices such as LCD panels and touch-screen displays has lead to an increased demand and to strong price volatility due to supply concerns. Furthermore, ITO has poor mechanical properties when deposited on flexible substrates, making it susceptible to cracks when the substrates are bent. In addition, there have been concerns of migration of indium from ITO into the emission layers during OLED operation, thereby decreasing their lifetime. Hence, developing an OLED architecture in which ITO is replaced with a transparent, low-cost, indium-free, and crack-tolerant electrode is of great interest. Furthermore, since demands for large-area OLEDs for display and lighting applications are increasing, uniform light emission and low-power consumption also must be considered. In this research, we investigate an ITO-free large-area organic light-emitting diodes (OLEDs) fabricated on glass substrates comprising α-NPD as a hole transport layer (HTL) and coevaporated CBP:Ir(ppy)3 as the emission layer. Indium-tin-oxide (ITO) was replaced with a conductive polymer electrode and an electroplated thick metal grid was used to improve the homogeneity of the potential distribution over the transparent polymer electrode. An electrical model of a metal grid integrated OLED shows the benefits of the use of metal grids in terms of improving the uniformity of the light emitted as the area of the OLED increases as well as the conductivity of the transparent electrode decreases. By integrating metal grids with polymer electrodes, the luminance increases more than 24% at 6 V and 45% at 7 V compared to the polymer electrode devices without a metal grid. This implies that a lower voltage can be applied to achieve the same luminance, hence lowering the power consumption. Furthermore, metal grid integrated OLEDs exhibited less variation in light emission compared to devices without a metal grid. |

|

Email: schoi [at] uwb.edu