About Me

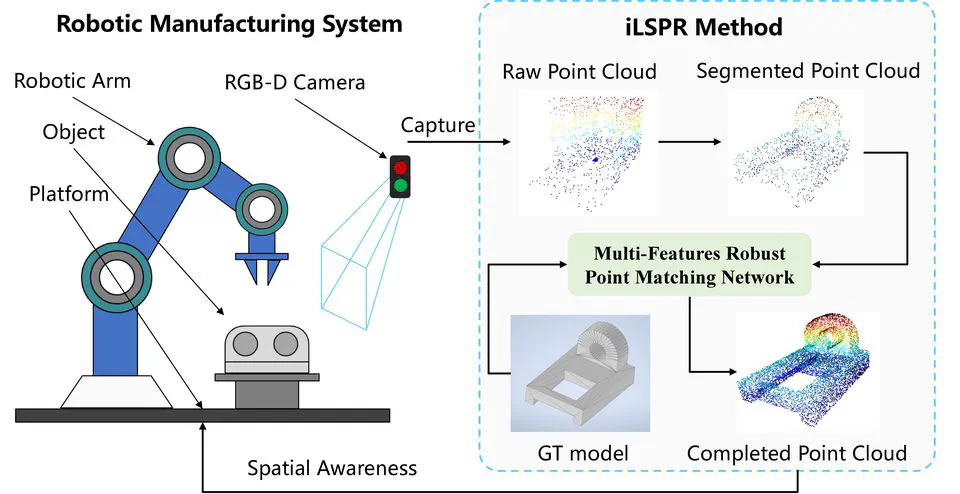

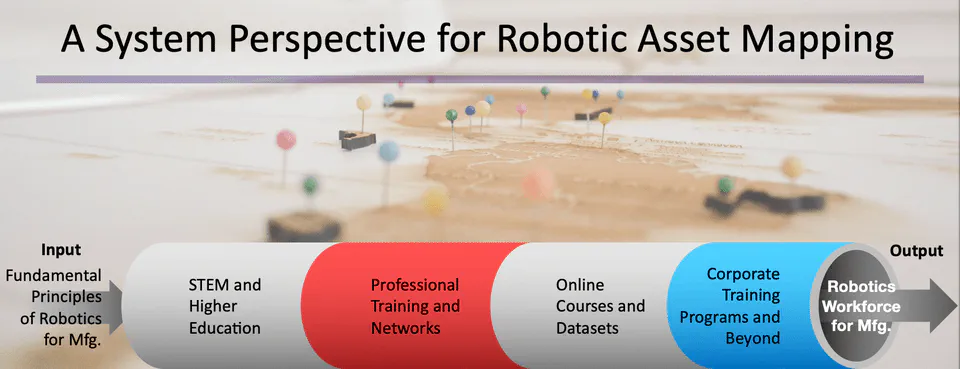

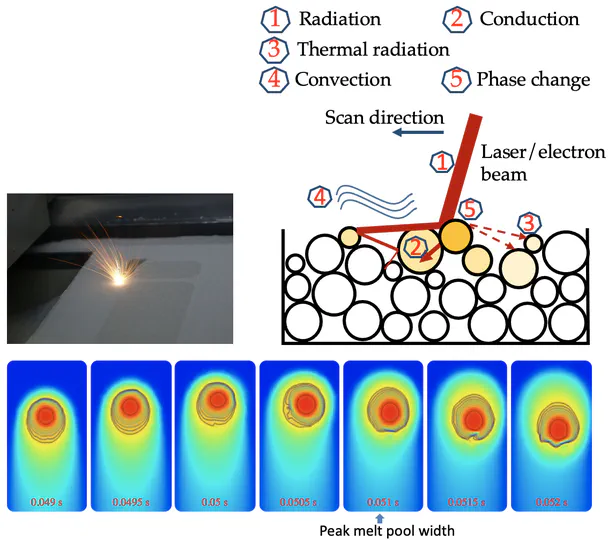

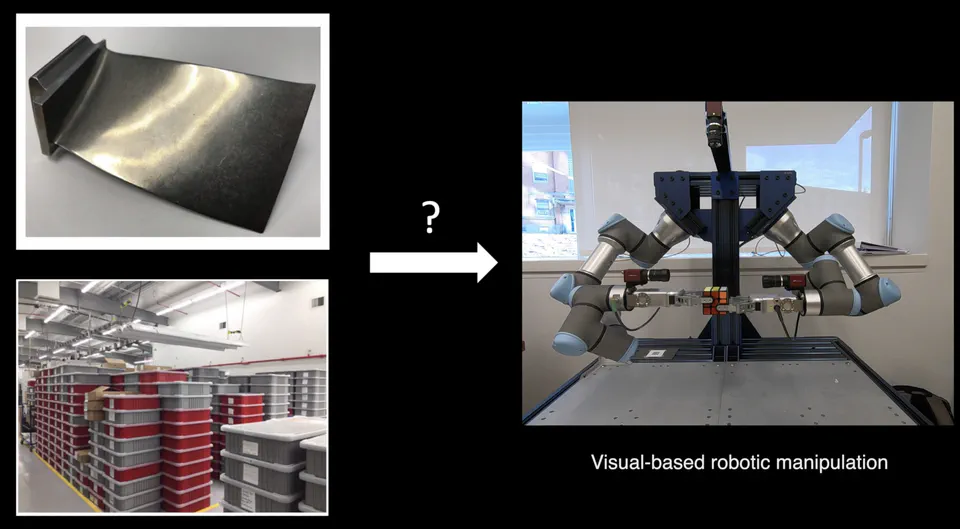

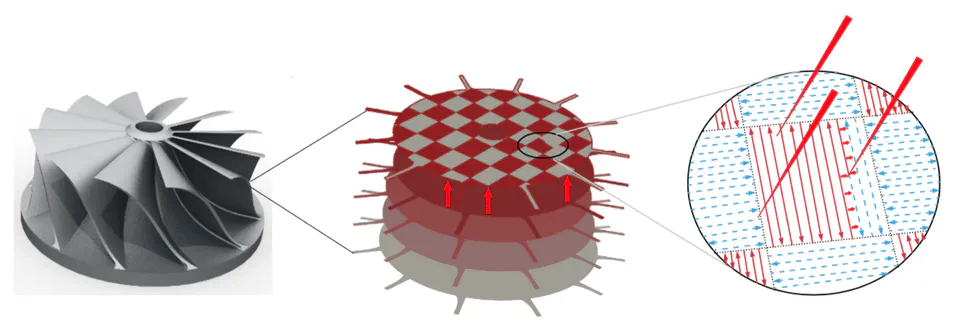

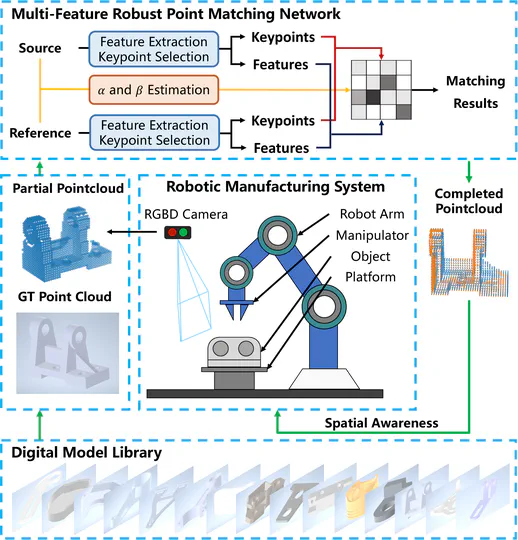

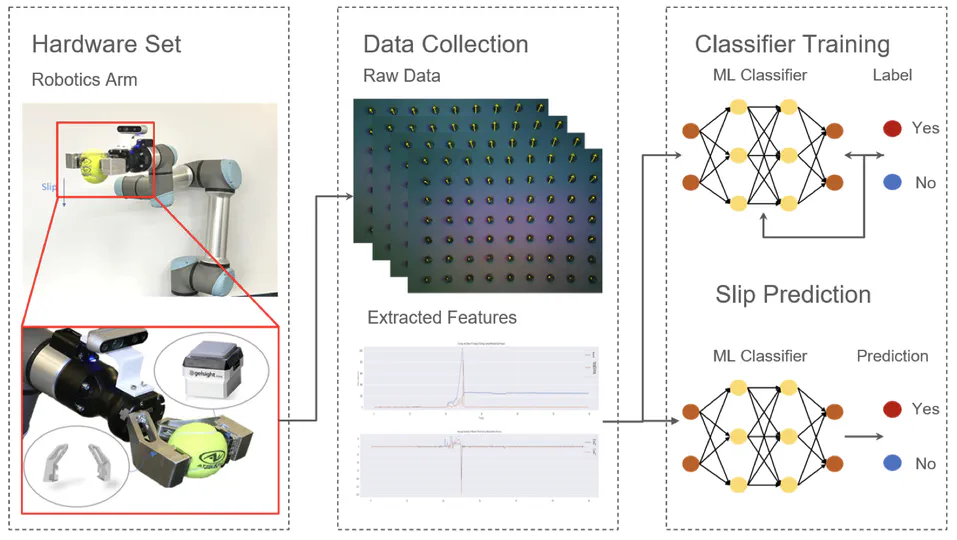

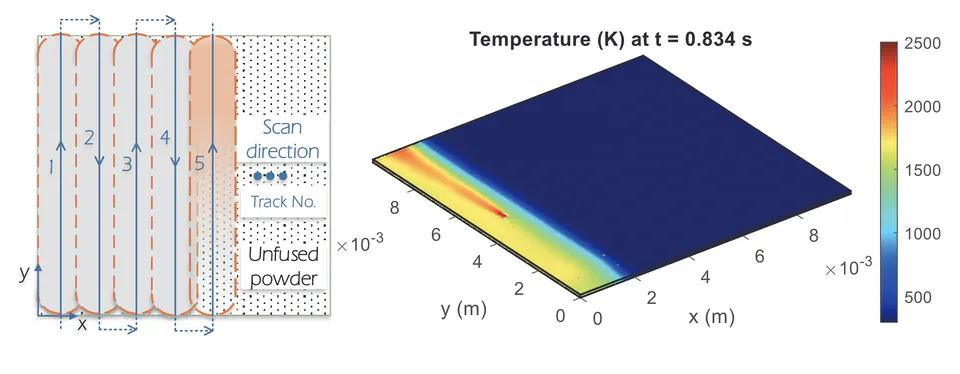

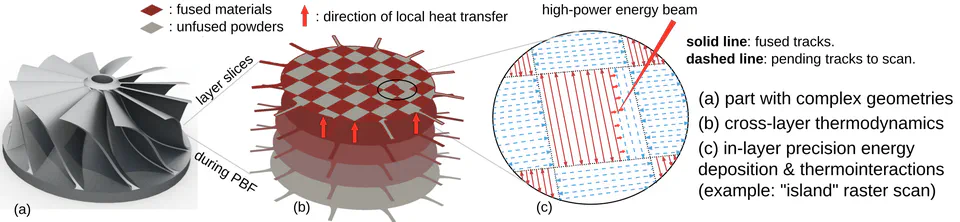

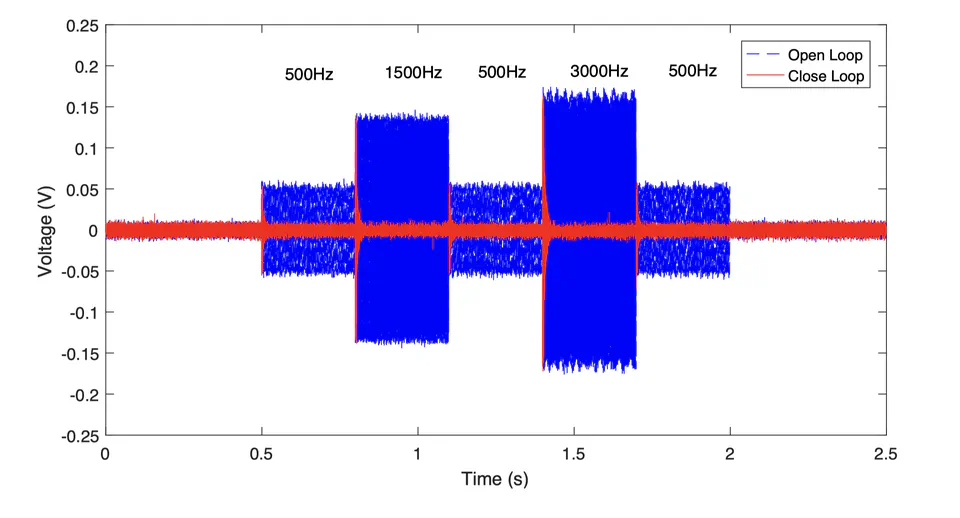

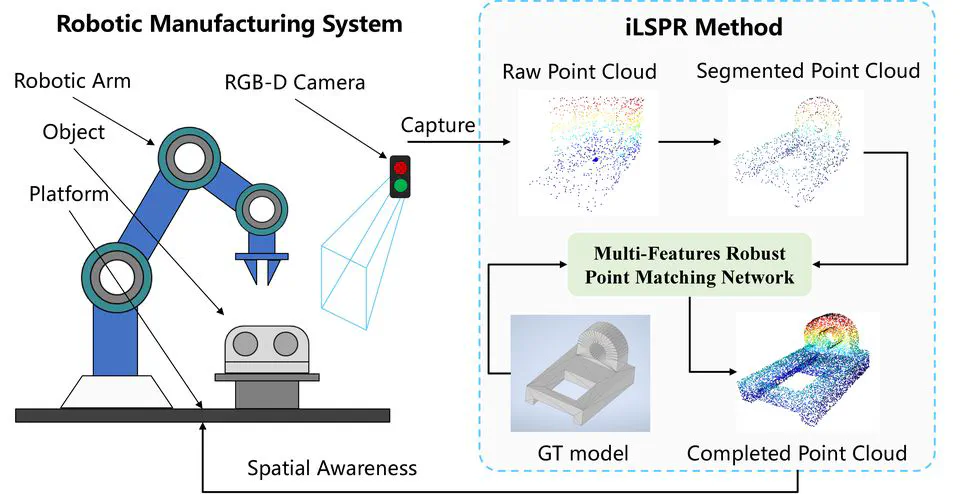

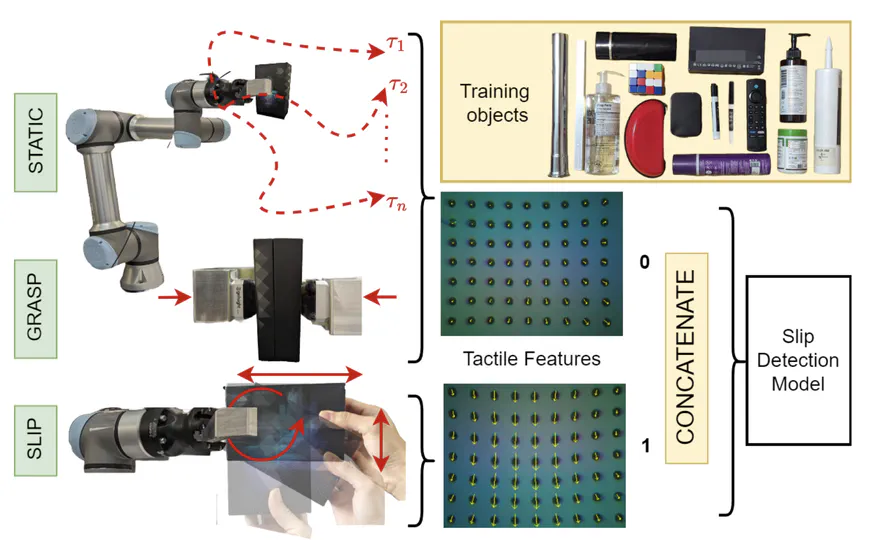

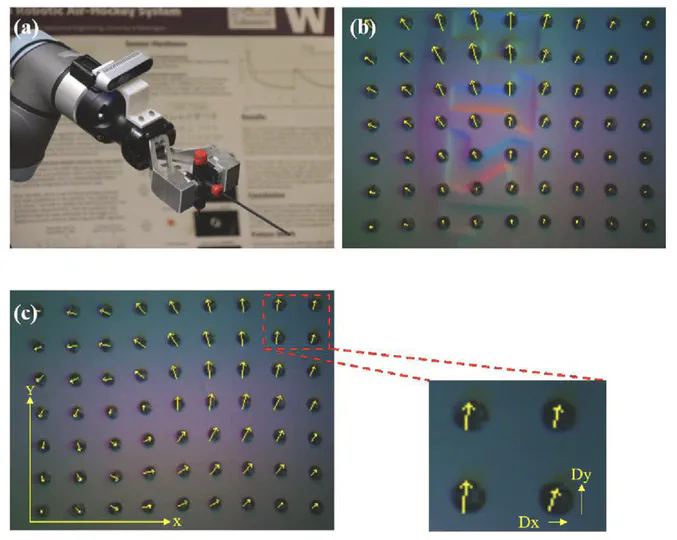

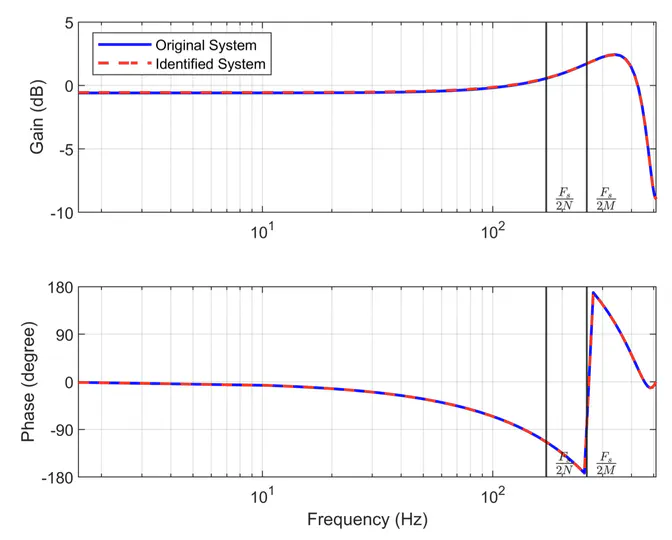

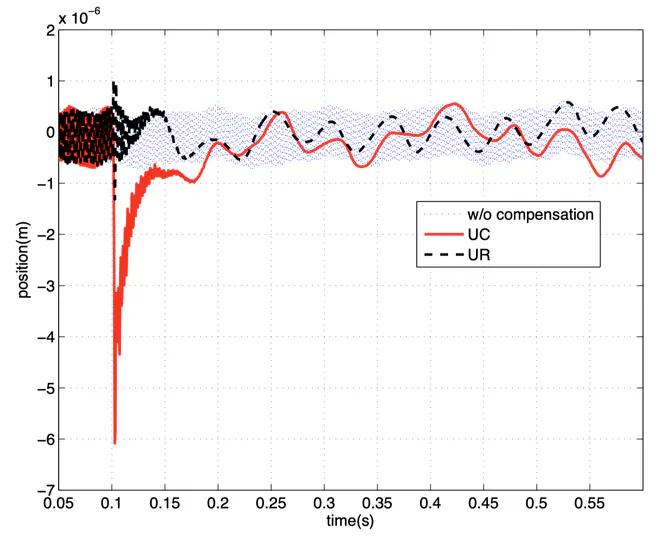

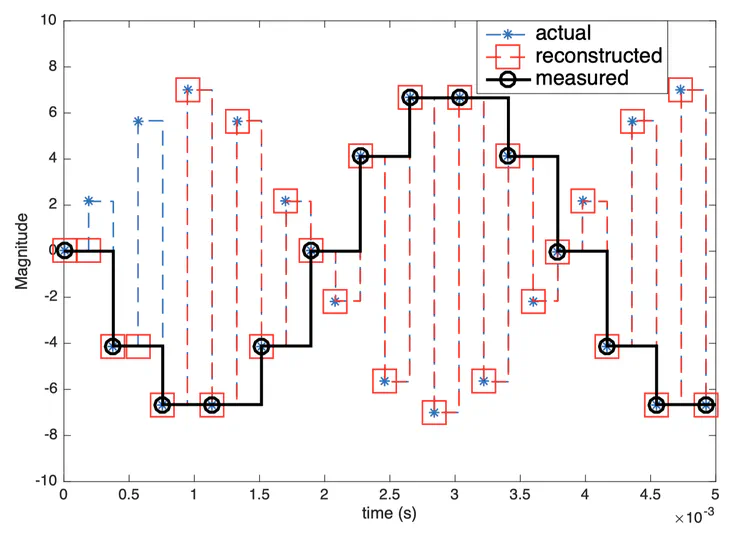

Xu Chen pursues a research passion at the intersection of dynamic systems, information processing, and controls, to better understand and engineer smart machines that positively impact our lives. He leads the MACS Lab — a team focusing on sensing, actuation, and automation that facilitate e.g., robots that inspect complex, highly reflective parts in aerospace, and additive manufacturing that make engineered materials with extraordinary properties at low unit costs compared to conventional machining. Xu Chen also serves as Director of the Boeing Advanced Research Collaboration at UW – an interdisciplinary Boeing-UW partnership for the future of flight. He is a recipient of the U.S. National Science Foundation CAREER Award, the SME Sandra L. Bouckley Outstanding Young Manufacturing Engineer Award, the IFAC Mechatronic Systems Outstanding Young Researcher Award, and the Young Investigator Award from ISCIE/ASME International Symposium on Flexible Automation. He is an alumnus of the US NAE Frontiers of Engineering.

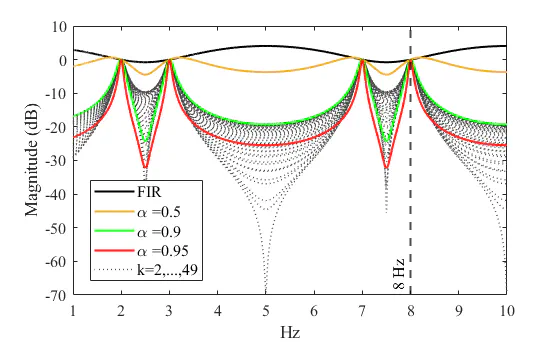

- Dynamic Systems

- Controls and Sensing

- Robotics and Manufacturing

- Artificial Intelligence

- Adaptation and Learning

-

PhD Mechanical Engineering

University of California, Berkeley

-

MS Mechanical Engineering

University of California, Berkeley

-

BS Mechanical Engineering

Tsinghua University

- 01/11/2024: New Book released: Introduction to Modern Controls, with Illustrations in Matlab and Python!

- From Funding to Impact: How ARM Institute Robotics Projects Strengthen U.S. Manufacturing, panelist, ARM Institute, “Robotic Inspection of Complex Metallic Parts,” March 6, 2024.

- National Academy of Engineering’s 2023 Frontiers in Engineering Symposium, subgroup presentation, “The Power of Feedback,” September 11-13, 2023

- Arizona State University, “The Power of Feedback: Closing the Loop of Machine Intelligence in Robotic Automated Inspection and Control under Mismatched Sensor Measurements,” March 31, 2023

- University of Sheffield Advanced Manufacturing Research Centre, “Robotics and AI in Manufacturing at the UW,” March 22, 2023

- Highlighted Project, DoD Advanced Robotics for Manufacturing Institute sponsor website and newsletter, “Automated Defect Inspection of Complex Metallic Parts,” April 27, 2022

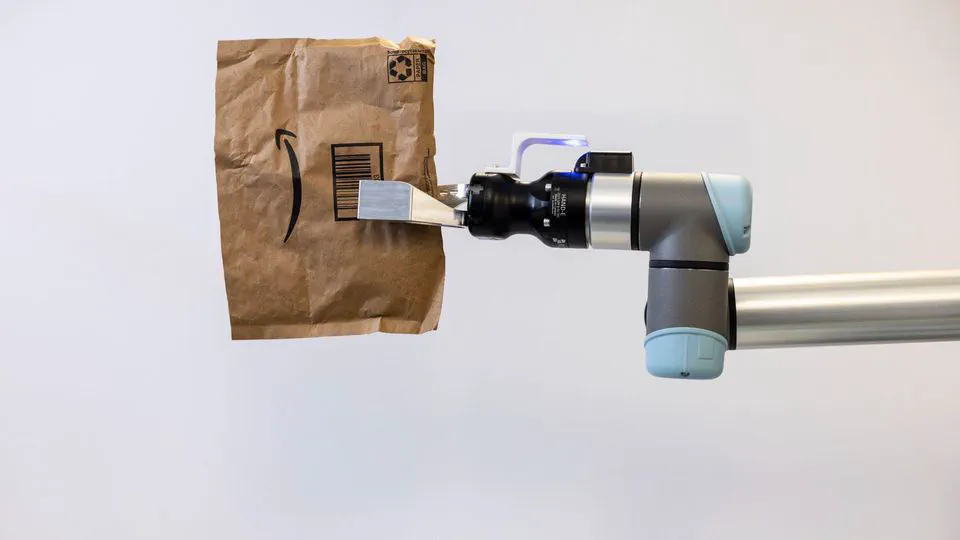

- Seattle Times Cover Article, Seattle, “Robots Are Learning to Think Like Humans. Can They Meet Amazon’s Demands for Speed?,” April 09, 2022

- Project Demonstration to DoD and Federal Stakeholders, ARM Institute, “Robotic Inspection of Complex Metallic Parts,” April, 2022: Selected as one of five on-site demonstration projects and the only project involving an academic team.

- IEEE Spectrum Video Friday, “How an Indusrial Robot Manipulator Learns to Play Chess (6th video in the list),” August 27, 2021

- Boeing Distinguished Researcher and Scholar Seminar (B-DRASS), “The Power of Feedback: From Closed-Loop Robotic Inspection and Grasping to Predictive Response under Limited Measurements,” July 18, 2023

- Boeing Distinguished Researcher and Scholar Seminar (B-DRASS), “Closing the Loop of Machine Intelligence in Robotic Data Collection and Automated Inspection,” September 27, 2022

- DoD JROBOT Monthly Robotics in Sustainment Working Group Teleconference, “Automated Defect Inspection of Complex Metallic Parts,” April 26, 2022

- DoD ISEA of the Future TECH Lunch and Learn, “Automated Defect Inspection of Complex Metallic Objects,” September 21, 2021

- Microsoft Surface Tech Talk, Seattle, “Automated Defect Inspection of Complex Metallic Parts,” April 21, 2021

- Highlighted Project, SME Media, Ilene Wolff, “ARM Counts Wire-harness Installation, Pop-up Boot Camp Among Its Successes,” September, 2020.

- University of Huston distinguished departmental seminar, Texas, “Control Across Different Temporal Scales – A Mechatronic-System Perspective,” November 5, 2020

- Highlighted Project, DoD Advanced Robotics for Manufacturing Institute membership meeting, “Automated Defect Inspection of Complex Metallic Parts,” October 13, 2020

- Highlighted Project, DoD Advanced Robotics for Manufacturing Institute sponsor website, “Automated Defect Inspection of Complex Metallic Parts,” October 13, 2020

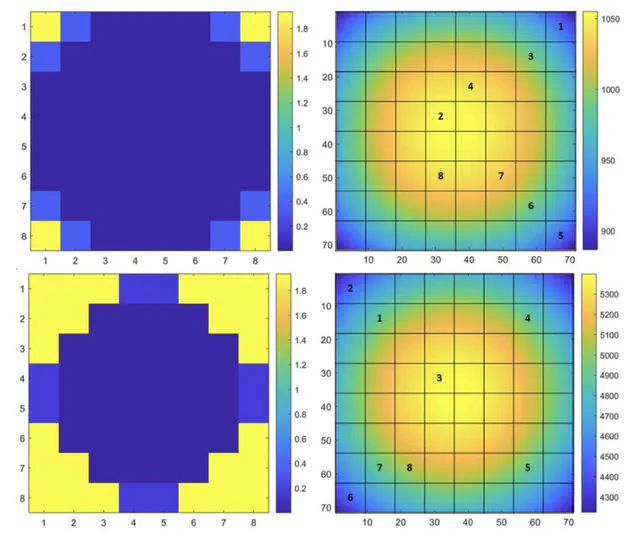

- Mechanical Engineering Byron Short Lecture, University of Texas at Austin, Austin, TX, “Adding to the Future: Sparse Sensing and Controls for Robust and Reliable Powder Bed Fusion,” February 9, 2018

- Panelist, DoD Advanced Robotics for Manufacturing Institute membership meeting, “Achievements Using AI/ML in Fab/finishing/logistic Processes and Their Impact,” October 14, 2020