Ch.E. 499 Project – Mixing and flow of polymers – Spring, 2005

SharpeMixers of Seattle proposed the following project (No. 1), which is pertinent to the Renton Waste Treatment Plant. In consultation with people at the Renton Plant, we have created several additional projects that are related. Students would work in pairs on one of the project, but all the projects would be tied together.

Joanne and Thin Thin

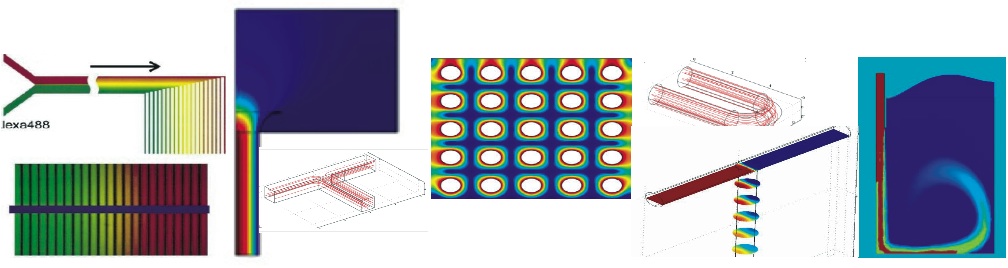

1. Model the flow of polymer when injected into a wastewater stream. The eventual goal is to determine at what location to put the injection port to insure good mixing at a certain point downstream. This project would use FEMLAB to do the simulations, since the flow is laminar.

Diana and Nick

2a. Investigate the efficiencies of static mixers. This project would use the same polymer, but analyze the flow in a 3D mixer rather than a pipe. The project would use FEMLAB, using (hopefully) a geometry already available from Comsol, the manufacturers of FEMLAB.

Toai and Steve

2b. Same as 2a, except do for a rotating mixer.

Albert and Sheena

3. Measure the viscosity of the polymer mixture as a function of shear rate and concentration of polymer. Then correlate the measurements so that the correlation can be used in the simulations of project 1 and 2. This work would be performed on-site at the Renton plant. It would have to be done early in the quarter in order for the results to be used by other projects.

Angelo and Dan

4. Make engineering estimates of the amount of chlorine lost in an open channel. It is necessary to have enough chlorine to kill any remaining bacteria once the water flows to Puget Sound, but too much causes problems (including cost), too. This would involved using engineering correlations to estimate the turbulent diffusion coefficient and the mass transfer coefficient at the surface.

Subject list (all projects)

Chronological list (all projects)