Mesh

Refinement Analysis for 3:1 Contraction

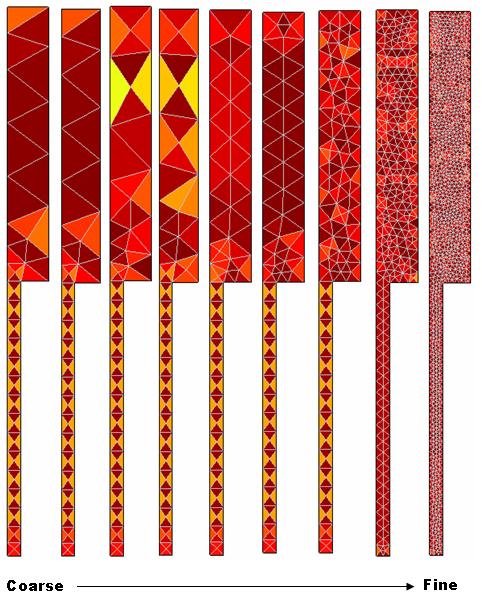

The purpose of this project is to investigate the effects

of mesh refinement for a standard 3:1 contraction. More specifically how increasing

mesh refinment (or decrease in mesh element size) correlates to error in excess

pressure drop. Figure 1, to the right shows visually how increased mesh refinement

looks for a 3:1 contraction case. The 9 refinements shown to the right reflect

9 preset mesh refinement settings within COSMOL Multiphysics software package.

Abhi

Banerjee

Figure

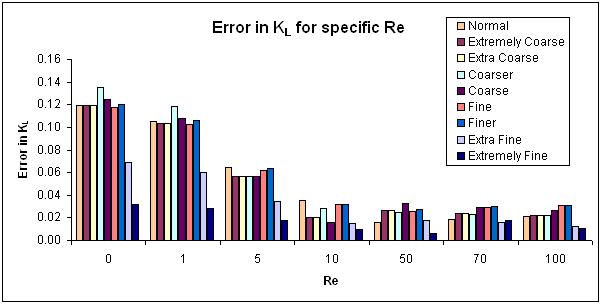

2, below, shows the error in the excess pressure drop distribution for different

refinement presets for different Reynolds numbers. Notice for small Reynolds

numbers the error difference between a fine mesh with a normal mesh is quite

dramatic. However, for a higher Reynolds number the difference in error associated

with the excess pressure drop is much lower.

Figure

1. Spectrum of mesh refinment presets in COSMOL Multiphysics software.

Figure

2 . Error distribution of excessive pressure drop for a 3:1 contraction

for different Reynolds numbers.

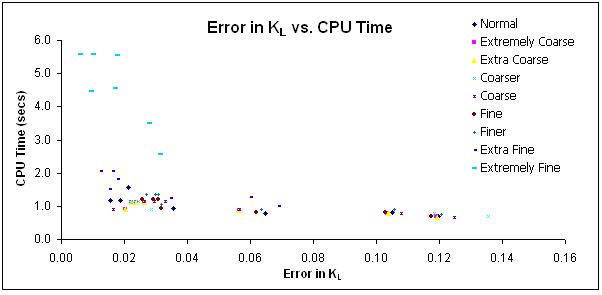

Figure

3 . Error in KL versus CPU time for different mesh refinment presets.

Figure

3, below is a graph of the CPU time versus error in excess pressure drop. As

one can see between figures 2 and 3, we see that for lower Reynolds numbers

there is a significant difference in the amoung of error between a normal refinement

and extremely fine refinement settings. This difference is much smaller for

higher Reynolds numbers.

Through

this research we found when a finer refinment mesh is required and when a normal

refinement is good enough. Although this analysis was done on a simple case

with a simple geometry. We expect the same trends to hold for more complex geometries

presented in COSMOL Multiphysics. For a more detailed calculations and discussion

of this research please refer to the formal

paper.

Micro06_home