The Semi-Continuous Process

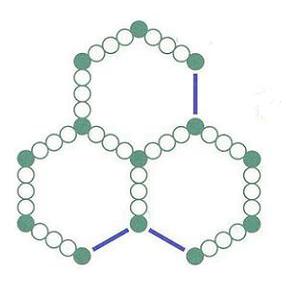

A process to scale-up the batch process in order to produce a roll of microcellular sheet was proposed by Kumar and Schirmer and is shown schematically below. Normally, if a roll of polymer film of say 10 cm thickness was put in the pressure vessel for saturation with gas, it would take hundreds of years at the typical rates of diffusion for the gas to achieve a uniform concentration throughout the polymer roll. The breakthrough idea in the semi-continuous process is that the polymer roll is first interleaved with a gas channeling device, such as a roll of paper towel. When this roll is now put in the pressure vessel, the entire roll gets saturated in the same amount of time that it takes for one polymer layer. As shown in the figure below, the gas-saturated roll is passed through a hot bath to create the foam, and a chilled bath to quench the microstructure, and the foamed polymer roll is collected as shown. The gas-channeling device (paper towel in the laboratory version of the process) can be collected and re-used. This process has been successfully used to produce PET microcellular sheets, which can then be thermoformed into desired shapes.