Gas-Impregnated Thermoforming

A process to foam and thermoform a gas-saturated sheet was first reported by Kumar and Suh. The gas dissolved in the polymer plasticizes the polymer, and make it easier to deform and shape the polymer. Thus if the foam sheet in the semi-continuous process is thermoformed while it still has a significant amount of gas in it, foamed articles can be produced in an energy-efficient process. This is known as the Gas-Impregnated Thermoforming process and has been successfully used to make thermoformed products such as a coffee cup from recycled PET.

Microcellular PET Hot Drink Cups!

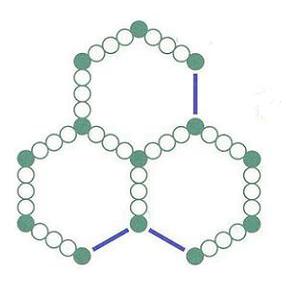

Solid-state foaming allows for variant microstructures throughout the thickness. The example cup microstructure shown above achieves higher rigidity by placing the bulk of the material furthest from the centerline. Controllable structure is just one of the many advantages of the solid-state process over convential foaming processes.