Neville E. Sanjana and Sawyer B. Fuller, Journal of Neuroscience Methods. (subscription required)

“Biology: the Ultimate Robotics,” story about this work in the MIT Tech Talk

neurodudes.com, Neville's theoretical neuroscience weblog

S. Fuller uses ink-jet printing to fabricate circuits and microscopic machines

Authors

Sawyer Fuller

Neville Sanjana

Contributing Professors

Shuguang Zhang

H. Sebastian Seung

Joseph Jacobson

Synopsis by Sawyer Fuller

We report growing neurons in networks defined by chemical patterns deposited by ink-jet printing. Our findings will enable new studies of nerve cell patterning, behaviors of small connected networks, and nerve regeneration and rehabilitation.

The growth and connection patterns of neural processes are carefully controlled by biology during development of the nervous system. The extending processes of neurons follow a step-by-step program telling them to adhere to certain cells and what gradients of hormonal cues to follow so that they eventually form synapses at the correct location.

In this work, we report the first known fabrication of these chemical patterns using ink-jet printing. Ink-jet printing is a widely-used and inexpensive technology used by desktop printers. These printers work by moving a print head over a flat surface while ejecting tiny 10-100 micrometer droplets of liquid ink through the air. When the droplets land, the liquid evaporates, leaving any solids in the "ink" behind. Its programmability and low cost make ink-jet a compelling technology for the lab bench.

Figure 1. Patterning neurons by ink-jet. The print

head

ejects microscopic droplets onto a treated coverslip to form a chemical

pattern made of tiny dots. The pattern is submerged in a petri dish with culture medium, and when neurons are added they settle to

the bottom, where they re-form synapses on the pattern.

To make ink-jet printed bio-active patterns, we built a custom printer that could deposit them onto glass. The patterning procedure consisted first of treating a glass coverslip with poly-ethylene glycol (PEG), a material that inhibits neurons' adhesion. On top of that a second material -- collagen ink -- was printed by ink-jet. In culture medium, dissociated primary rat hippocampal neurons settled onto and adhered to the pattern, forming functioning synapses (Figure 1).

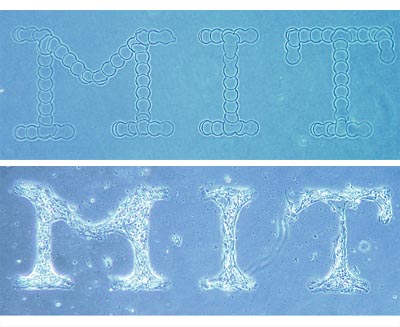

Figure 2. Ink-jet printed pattern showing individual dots produced by the ink droplets (top) and neurons confined to pattern (bottom). Each dot is approximately 70 micrmeters in diameter.

Figure 3. A current trace showing spontaneous spiking activity observed in the patterned neurons.

We have shown that ink-jet printing can fabricate chemical patterns that neurons will respond to. Ink-jet printing is quickly programmable and uses technology widely proven on the desktop, in contrast to other printing technologies such as micro-stamping. We have even demonstrated gradients and three-dimensional structures in preliminary form. The results suggest a route to a "desktop fab" for systematic ink-jet chemical pattern experiments right on the laboratory bench. Possible applications include careful control of growing axons by multiple "colors" of chemical patterns, creating islands of neurons to study small-network behavior, or building 2D or 3D bio-scaffolds for nerve regeneration and rehabilitation for spinal-cord injuries.

Special thanks to Profs. Sebastian Seung,

Shuguang

Zhang, and Joseph Jacobson for insight and facilities. This work was

funded by the Defense

Advanced Project Research Agency/BioComp, NSF CCR-0122419 to MIT’s

Media Laboratory Center for Bits and Atoms for the printer, and a

Whitaker Foundation grant to Shuguang Zhang. H. Sebastian Seung is

funded by the David and Lucille Packard Foundation and the Howard

Hughes Medical Institute.