Robots that remedy burdensome and subjective human inspections.

Jul 22, 2020

Towards an agile manufacturing of quality-assured, short-run products.

Jul 22, 2020

Help build a national robotic resource map for manufacturing.

Jul 22, 2020

Building robots that combine vision, AI, and manipulation to play games, perform tasks, and advance research.

Jul 22, 2020

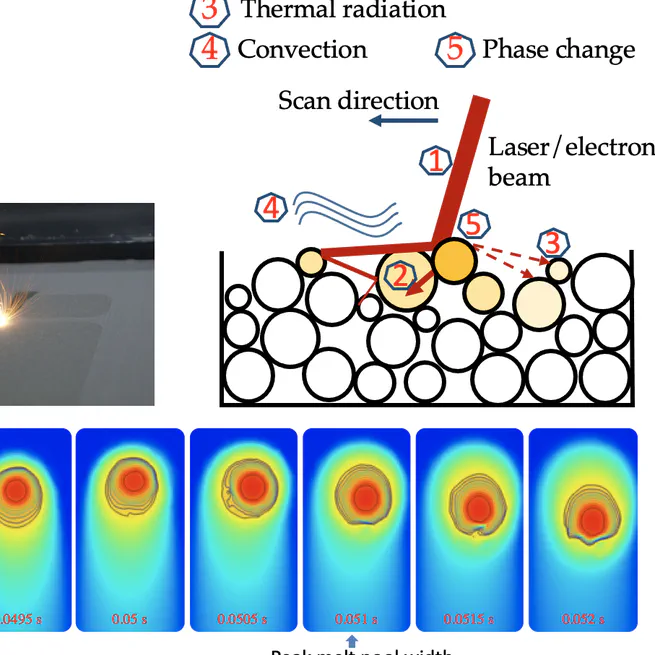

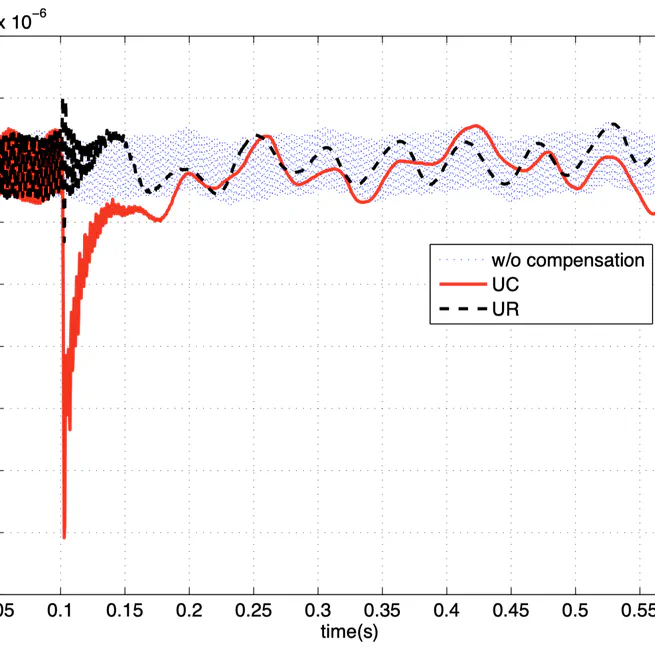

Dan Wang and I received the Best Paper Award on July 19, 2018, at the Japan Institute of Systems, Control, and Information Engineers (ISCIE) / ASME International Symposium on Flexible Automation. Our paper, titled “Synthesis and analysis of multirate repetitive control for fractional-order periodic disturbance rejection in powder bed fusion,” represents a significant step forward in advancing additive manufacturing control techniques.

Jul 19, 2018

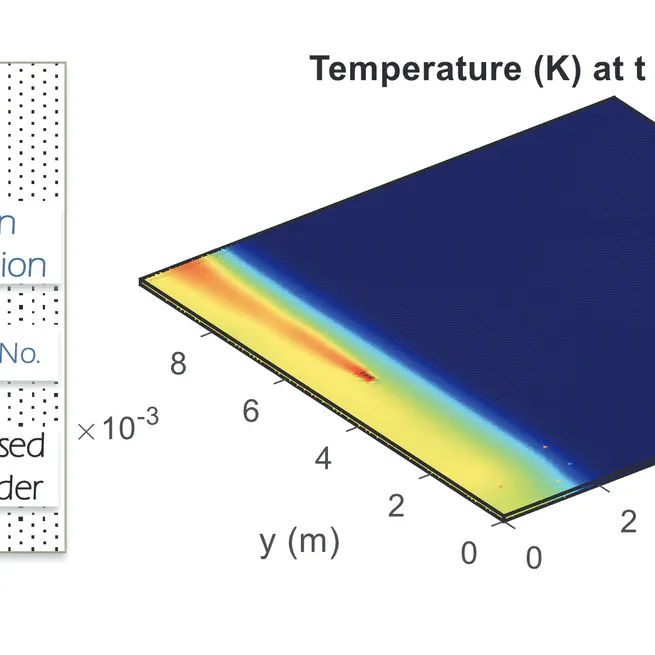

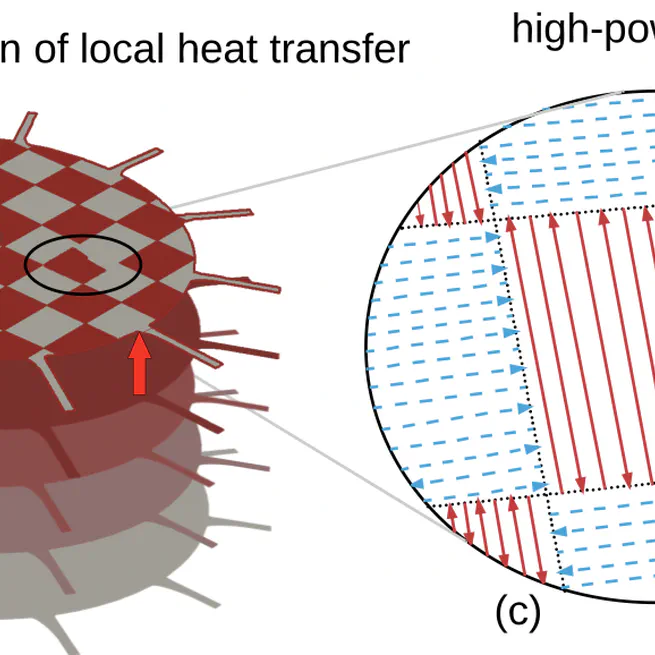

This Faculty Early Career Development Program (CAREER) project researches into substantially higher accuracy and greater reproducibility in additive manufacturing (AM) processes. In contrast to conventional machining, where parts are made by cutting away unwanted material, additive manufacturing – also called 3D printing – builds three-dimensional objects of unprecedented complexity by progressively adding small amounts of material. Powder bed fusion (PBF), in which new material is added to the part being fabricated by applying and selectively melting a powdered feedstock, is a popular form of AM for fabricating complex metallic or high-performance polymeric parts. This project supports fundamental research to create new thermal modeling, sensing, and control algorithms that will lead to precise and reliable PBF. The modeling task will enable fast and accurate prediction of heat flow and temperature distribution during powder fusion. The resulting knowledge on directing heat flow is essential for achieving a desired three-dimensional shape. The sensing task will formulate new signal processing algorithms that discard unnecessary information to make full use of data-intensive sensor sources like high-speed video. Finally, these results will be integrated with new control algorithms in order to counteract process variations and provide repeatable, low-cost, high-quality parts. AM offers untapped potential in a wide range of products for the energy, aerospace, automotive, healthcare, and biomedical industries. PBF parts are increasingly preferred in applications ranging from advanced jet-engine components to custom-designed medical implants. The project creates new knowledge that will facilitate fabrication of products to benefit the US economy and improve quality of life. Broader impacts of the project will be augmented by dissemination of educational results to inculcate skills for innovative problem solving into undergraduate engineering education. Read more here.

Mar 15, 2018

Mar 1, 2018

I am deeply honored to have received the ISFA Young Investigator Award on July 16, 2014, at the ISCIE/ASME International Symposium on Flexible Automation. This award recognizes young researchers (aged 35 or younger) for their contributions to the field of flexible automation, encompassing impactful publications, patents, and collaborative work. The citation graciously acknowledged my efforts in advancing industrial production research and my contributions to collaboration and communication in the field.

Jul 16, 2014