|

|

|

AIR Lab Autonomous Insect Robotics Laboratory Department of Mechanical Engineering, University of Washington Prof. Sawyer B. Fuller, Principal Investigator Mech. Eng. Bldg. (MEB) Room 113

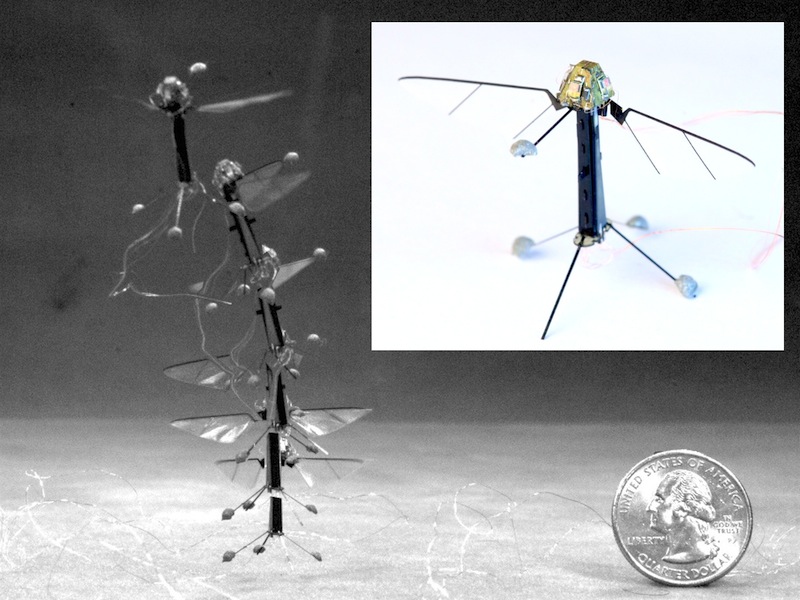

The Autonomous Insect Robotics Laboratory develops technology aimed at insect-sized robots. The goal is to create tiny robots capable of sensing and performing in the world without a human operator. A key driver is inspiration from the mechanics and sensorimotor systems of insects. The laboratory has facilities to microfabricate and control ground and aerial vehicles and is housed in a 500 sq. ft. space on the first floor of the Mechanical Engineering building. For more background, see the page of Prof. Sawyer B. Fuller.

|

| Facilities | |

Ultraviolet Laser Micromachining System

Ultraviolet Laser Micromachining System

| This system employs an ultraviolet (355 nm wavelength) laser that, unlike traditional CO2 lasers (10000 nm), is capable of cutting almost any material including aircraft-grade carbon fiber composites, metals, and ceramics. The spot size is approximately 10 micrometers. A cut takes a matter of a few minutes; layers of machined rigid and compliant materials can be laminated together to form flexures and actuators. These can be combined to create sophisticated, articulated mechanisms inspired by insects and origami. |

|

| |

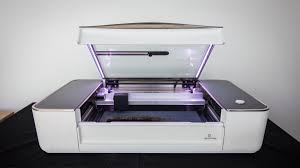

Glowforge CO2 Laser Cutter

Glowforge CO2 Laser Cutter

| This tool can cut many plastics and cellulosic (paper) materials, allowing for rapid fabrication of large-scale prototypes for testing purposes. |

|

| |

4K CAD workstation

4K CAD workstation

| |

|

| |

Microscopic assembly station

Microscopic assembly station

| For assembly under a microscope. |

|

| |

Precision solder station

Precision solder station

| Precision wiring and electronics. |

|

| |

Hydraulic heat press | For press curing prepreg carbon fiber composites and performing pin-aligned heat press layups. |

|

| |

| Insect-scale flight arena (to come) | Perform free-flight control experiments on insect robot prototypes. |