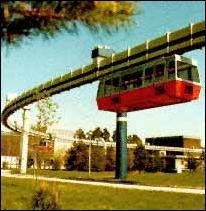

SIPEM - Siemens People Mover System

SIPEM is the latest version of a German technology

that was originally called H-Bahn, a suspended monorail transit system. The first system

started revenue passenger service in 1984 in Dortmund. This installation was preceded by a

test system at the Siemens Research Center at Erlangen in cooperation with DUWAG AG. The

system in Dortmund is the first automatically-controlled urban transit system in Germany.

By 1991, it had carried more than 5 million passengers without an accident. The initial

line was built at Dortmund University and linked two university campuses (see H-Bahn web site at Dortmund University)

SIPEM is the latest version of a German technology

that was originally called H-Bahn, a suspended monorail transit system. The first system

started revenue passenger service in 1984 in Dortmund. This installation was preceded by a

test system at the Siemens Research Center at Erlangen in cooperation with DUWAG AG. The

system in Dortmund is the first automatically-controlled urban transit system in Germany.

By 1991, it had carried more than 5 million passengers without an accident. The initial

line was built at Dortmund University and linked two university campuses (see H-Bahn web site at Dortmund University)

It has since been extended beyond the confines of the university

into a residential area. Another extension provides a link to a rapid transit (S-Bahn)

station at the university. The new station at Eichlinghofen is at ground level so

passengers alighting from buses do not have to use stairs to reach the platform. A second

station has been situated directly over the S-Bahn tunnel so that an elevator can bring

passengers right to the S-Bahn platform. Most recently, SIPEM is being used to connect a

high speed rail station with the terminal at Duesseldorf International Airport. It is

called SkyTrain

and is now (2003) operational. Information about this application is

provided. Two photos of the early stages of construction are

available as is more information at the Duesseldorf International Airport website.

It has since been extended beyond the confines of the university

into a residential area. Another extension provides a link to a rapid transit (S-Bahn)

station at the university. The new station at Eichlinghofen is at ground level so

passengers alighting from buses do not have to use stairs to reach the platform. A second

station has been situated directly over the S-Bahn tunnel so that an elevator can bring

passengers right to the S-Bahn platform. Most recently, SIPEM is being used to connect a

high speed rail station with the terminal at Duesseldorf International Airport. It is

called SkyTrain

and is now (2003) operational. Information about this application is

provided. Two photos of the early stages of construction are

available as is more information at the Duesseldorf International Airport website.

This suspended monorail technology is reported to

have a capacity of 15,000 passengers per hour per direction which puts it in an

intermediate category. The minimum headway (time interval between vehicles) is 6 seconds,

and its active switches can operate in less than 5 seconds. The maximum capacity of the

vehicle is 65 passengers and its maximum speed is 65 kph. Its steel guideway is

prefabricated off-site and can be erected quickly with minimum disruption to normal road

traffic. An illustration of this construction concept is

provided.

This suspended monorail technology is reported to

have a capacity of 15,000 passengers per hour per direction which puts it in an

intermediate category. The minimum headway (time interval between vehicles) is 6 seconds,

and its active switches can operate in less than 5 seconds. The maximum capacity of the

vehicle is 65 passengers and its maximum speed is 65 kph. Its steel guideway is

prefabricated off-site and can be erected quickly with minimum disruption to normal road

traffic. An illustration of this construction concept is

provided.

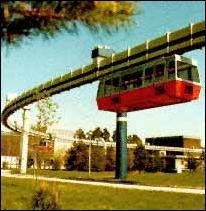

![[Dortmund University view]](sipem3.gif) The average distance between guideway columns is 25

m, the maximum is 35 m. According to the vendor, it is automatic and driverless, easy to

construct, independent of road traffic conditions, friendly to the environment,

comfortable, capable of all-weather operation, safe, reliable, economical and flexible. It

can be operated in a fixed cycle mode or in a demand-responsive mode that permits a

precise adaptation to normal changes in demand throughout the day.

The average distance between guideway columns is 25

m, the maximum is 35 m. According to the vendor, it is automatic and driverless, easy to

construct, independent of road traffic conditions, friendly to the environment,

comfortable, capable of all-weather operation, safe, reliable, economical and flexible. It

can be operated in a fixed cycle mode or in a demand-responsive mode that permits a

precise adaptation to normal changes in demand throughout the day.

So far as is known, it has not been installed

anywhere other than Dortmund and the Dusseldorf International Airport. Project-specific

cost data are available from the vendor. Applications in residential areas, technology

parks, shopping centers, park/ride schemes, airports and as feeder/distributor connectors

to high capacity rail systems are thought to represent the best market niche for this

transit technology. Illustrations of these ideas are provided.

So far as is known, it has not been installed

anywhere other than Dortmund and the Dusseldorf International Airport. Project-specific

cost data are available from the vendor. Applications in residential areas, technology

parks, shopping centers, park/ride schemes, airports and as feeder/distributor connectors

to high capacity rail systems are thought to represent the best market niche for this

transit technology. Illustrations of these ideas are provided.

Information and graphics have been provided by: Siemens AG, Transportation Systems

Group, Turnkey Systems, Mass Transit, Werner-von-Siemens-Strasse 50, W-8520 Erlangen,

Germany. Tel: ++49-9131-727076; Fax: ++49-9131-726045.

Three sketches of SIPEM construction methods and vehicle

attributes

Four sketches of SIPEM application concepts

In 1998, the Siemens Company purchased MATRA, a French transit systems company. As a

result, it is reported that a decision has been made to drop SIPEM as a product and to go

forward only with the French VAL technology. Therefore, SIPEM should no longer be

considered to be a product offered by Siemens.

Last modified: October 08, 2010

SIPEM is the latest version of a German technology

that was originally called H-Bahn, a suspended monorail transit system. The first system

started revenue passenger service in 1984 in Dortmund. This installation was preceded by a

test system at the Siemens Research Center at Erlangen in cooperation with DUWAG AG. The

system in Dortmund is the first automatically-controlled urban transit system in Germany.

By 1991, it had carried more than 5 million passengers without an accident. The initial

line was built at Dortmund University and linked two university campuses (see H-Bahn web site at Dortmund University)

SIPEM is the latest version of a German technology

that was originally called H-Bahn, a suspended monorail transit system. The first system

started revenue passenger service in 1984 in Dortmund. This installation was preceded by a

test system at the Siemens Research Center at Erlangen in cooperation with DUWAG AG. The

system in Dortmund is the first automatically-controlled urban transit system in Germany.

By 1991, it had carried more than 5 million passengers without an accident. The initial

line was built at Dortmund University and linked two university campuses (see H-Bahn web site at Dortmund University)  It has since been extended beyond the confines of the university

into a residential area. Another extension provides a link to a rapid transit (S-Bahn)

station at the university. The new station at Eichlinghofen is at ground level so

passengers alighting from buses do not have to use stairs to reach the platform. A second

station has been situated directly over the S-Bahn tunnel so that an elevator can bring

passengers right to the S-Bahn platform. Most recently, SIPEM is being used to connect a

high speed rail station with the terminal at Duesseldorf International Airport. It is

called SkyTrain

and is now (2003) operational. Information about this application is

provided. Two photos of the early stages of construction are

available as is more information at the Duesseldorf International Airport website.

It has since been extended beyond the confines of the university

into a residential area. Another extension provides a link to a rapid transit (S-Bahn)

station at the university. The new station at Eichlinghofen is at ground level so

passengers alighting from buses do not have to use stairs to reach the platform. A second

station has been situated directly over the S-Bahn tunnel so that an elevator can bring

passengers right to the S-Bahn platform. Most recently, SIPEM is being used to connect a

high speed rail station with the terminal at Duesseldorf International Airport. It is

called SkyTrain

and is now (2003) operational. Information about this application is

provided. Two photos of the early stages of construction are

available as is more information at the Duesseldorf International Airport website.  This suspended monorail technology is reported to

have a capacity of 15,000 passengers per hour per direction which puts it in an

intermediate category. The minimum headway (time interval between vehicles) is 6 seconds,

and its active switches can operate in less than 5 seconds. The maximum capacity of the

vehicle is 65 passengers and its maximum speed is 65 kph. Its steel guideway is

prefabricated off-site and can be erected quickly with minimum disruption to normal road

traffic. An illustration of this construction concept is

provided.

This suspended monorail technology is reported to

have a capacity of 15,000 passengers per hour per direction which puts it in an

intermediate category. The minimum headway (time interval between vehicles) is 6 seconds,

and its active switches can operate in less than 5 seconds. The maximum capacity of the

vehicle is 65 passengers and its maximum speed is 65 kph. Its steel guideway is

prefabricated off-site and can be erected quickly with minimum disruption to normal road

traffic. An illustration of this construction concept is

provided.![[Dortmund University view]](sipem3.gif) The average distance between guideway columns is 25

m, the maximum is 35 m. According to the vendor, it is automatic and driverless, easy to

construct, independent of road traffic conditions, friendly to the environment,

comfortable, capable of all-weather operation, safe, reliable, economical and flexible. It

can be operated in a fixed cycle mode or in a demand-responsive mode that permits a

precise adaptation to normal changes in demand throughout the day.

The average distance between guideway columns is 25

m, the maximum is 35 m. According to the vendor, it is automatic and driverless, easy to

construct, independent of road traffic conditions, friendly to the environment,

comfortable, capable of all-weather operation, safe, reliable, economical and flexible. It

can be operated in a fixed cycle mode or in a demand-responsive mode that permits a

precise adaptation to normal changes in demand throughout the day. So far as is known, it has not been installed

anywhere other than Dortmund and the Dusseldorf International Airport. Project-specific

cost data are available from the vendor. Applications in residential areas, technology

parks, shopping centers, park/ride schemes, airports and as feeder/distributor connectors

to high capacity rail systems are thought to represent the best market niche for this

transit technology. Illustrations of these ideas are provided.

So far as is known, it has not been installed

anywhere other than Dortmund and the Dusseldorf International Airport. Project-specific

cost data are available from the vendor. Applications in residential areas, technology

parks, shopping centers, park/ride schemes, airports and as feeder/distributor connectors

to high capacity rail systems are thought to represent the best market niche for this

transit technology. Illustrations of these ideas are provided.