Jun 21, 2023

I am deeply honored to have received the Mechatronic Systems Outstanding Young Researcher Award alongside my esteemed colleague, Professor Juan Ren (Iowa State University), from the International Federation of Automatic Control (IFAC) Technical Committee on Mechatronic Systems.

Sep 8, 2022

SME fosters connections among manufacturing professionals, academia, and communities, sharing knowledge and resources to cultivate inspired, educated, and successful manufacturers and enterprises. In 2022, 22 Sandra L. Bouckley Outstanding Young Manufacturing Engineers, all aged 35 or younger, were honored for their exceptional contributions and achievements in advancing the manufacturing industry. I was truly honored to be among this group of distinguished awardees, recognized for my contributions to the field.

Apr 21, 2022

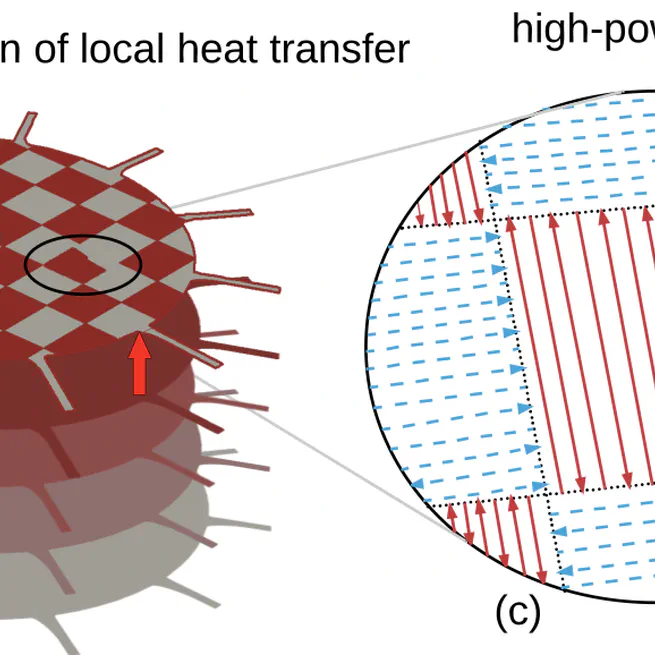

This Faculty Early Career Development Program (CAREER) project researches into substantially higher accuracy and greater reproducibility in additive manufacturing (AM) processes. In contrast to conventional machining, where parts are made by cutting away unwanted material, additive manufacturing – also called 3D printing – builds three-dimensional objects of unprecedented complexity by progressively adding small amounts of material. Powder bed fusion (PBF), in which new material is added to the part being fabricated by applying and selectively melting a powdered feedstock, is a popular form of AM for fabricating complex metallic or high-performance polymeric parts. This project supports fundamental research to create new thermal modeling, sensing, and control algorithms that will lead to precise and reliable PBF. The modeling task will enable fast and accurate prediction of heat flow and temperature distribution during powder fusion. The resulting knowledge on directing heat flow is essential for achieving a desired three-dimensional shape. The sensing task will formulate new signal processing algorithms that discard unnecessary information to make full use of data-intensive sensor sources like high-speed video. Finally, these results will be integrated with new control algorithms in order to counteract process variations and provide repeatable, low-cost, high-quality parts. AM offers untapped potential in a wide range of products for the energy, aerospace, automotive, healthcare, and biomedical industries. PBF parts are increasingly preferred in applications ranging from advanced jet-engine components to custom-designed medical implants. The project creates new knowledge that will facilitate fabrication of products to benefit the US economy and improve quality of life. Broader impacts of the project will be augmented by dissemination of educational results to inculcate skills for innovative problem solving into undergraduate engineering education. Read more here.

Mar 15, 2018