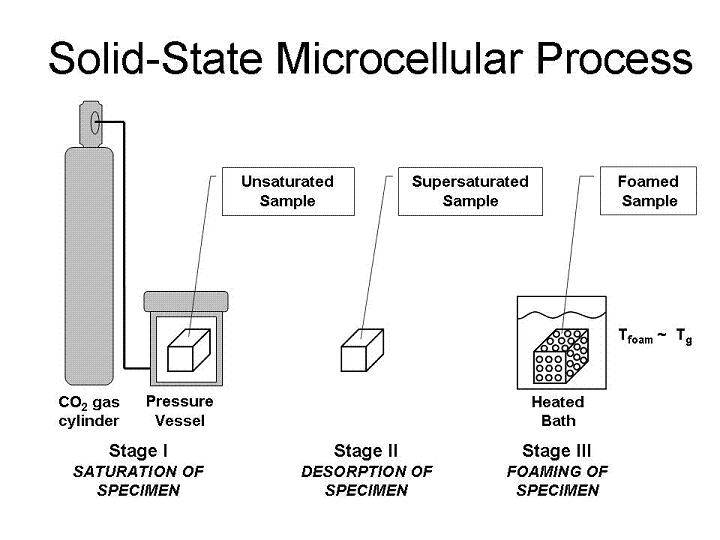

The Solid-State Batch Process

The basic solid-state microcellular process is a three-stage batch process shown schematically below.

In the first stage, the polymer is placed in a pressure vessel with a high-pressure and a non-reacting gas. This step is usually conducted at room temperature. Over time, the gas diffuses into the polymer, and attains a uniform concentration throughout the polymer specimen.

The second stage occurs when the specimen is removed from the pressure vessel and brought to atmospheric pressure. The specimen is in a ‘supersaturated’ state meaning that it is thermodynamically unstable due to the excessive gas dissolved into the polymer.

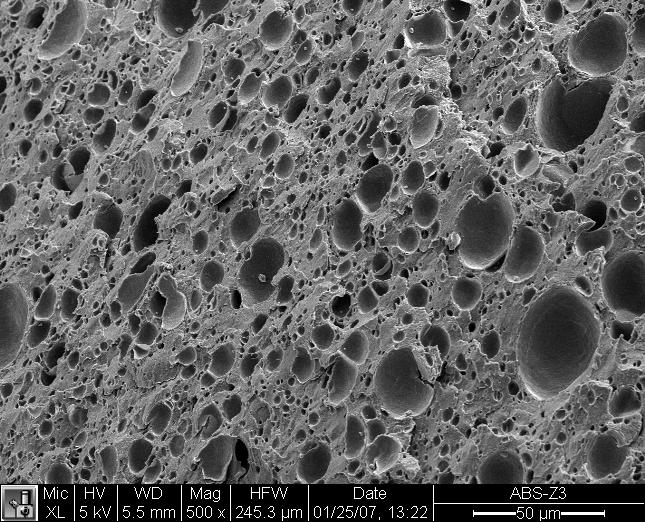

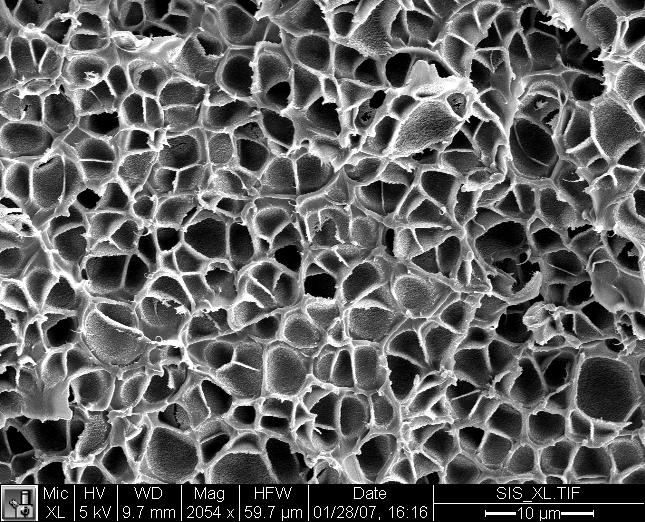

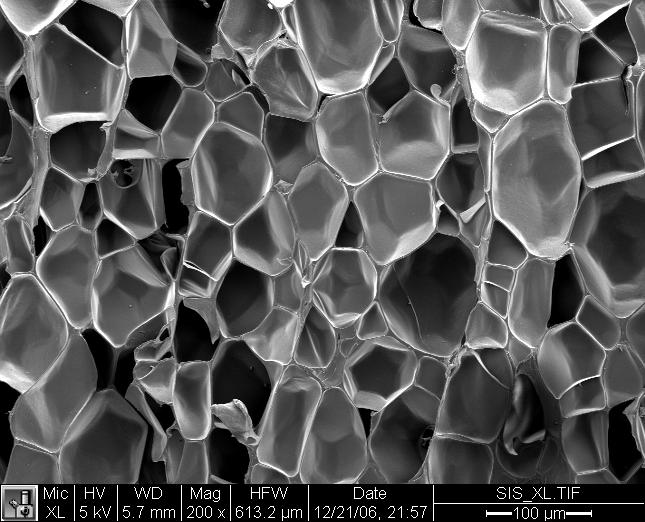

In the third stage, the supersaturated specimen is heated to a temperature above the glass transition temperature (Tg) of the polymer-gas mixture, termed the foaming temperature. This step is typically carried out in a heated bath with temperature control. Since the polymer is still in a solid state, the foams thus produced are called ‘solid-state foams’ to distinguish them from conventional foams that are typically produced in extrusion from a polymer melt. A number of polymers have been studied in this process such as, for example, PC, PET, ABS, and PVC. Some examples of solid-state microcellular structures in several polymers are shown below. The microcellular structure is remarkably uniform compared to the structure in extruded foams or structural foams.

Microcellular ABS

Microcellular PEI

Microcellular PLA