Microcellular Extrusion

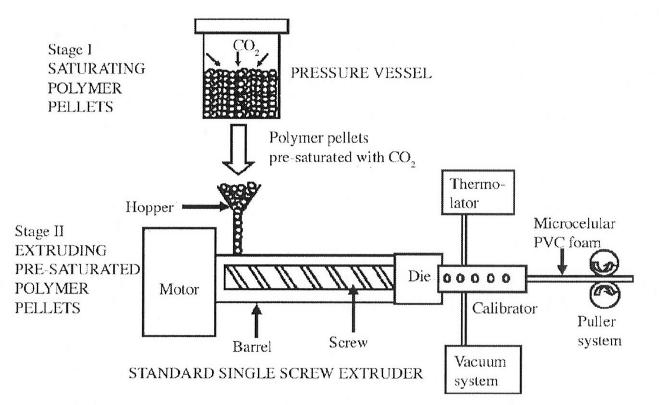

A novel process for continuous production of microcellular foams has been developed and applied to make flat microcellular strips from PVC. The first novel aspect of the process consists of the way in which the blowing agent, or gas, is delivered to the extruder. We pre-saturate the solid PVC pellets with carbon dioxide. The gas-saturated pellets are then put in the extruder hopper. The second novel aspect of the process is in applying nucleation in the solid state to continuous extrusion. As the pellets are crushed and heated in the extruder, a large number of bubbles nucleate as the temperature reaches the glass transition temperature of the CO&sub2 plasticized PVC. The melt thus is full of nucleated bubbles that are not able to grow in size due to the pressure that develops in the barrel. When the melt exits at the die, where the pressure is atmospheric, the bubbles have a chance to grow larger and create foam. The process employs effective cooling strategies at the die exit, including lower melt temperatures, to keep the bubbles in the microcellular range.