2.007: License to Design. Also Known

As 2.70

This page is about the robot I built

for the class 2.007:

Introduction to Mechanical design, one of MIT's most famous courses

which culminates in a competition event staged in front of 400 people

and occasionally a national audience.

THE RULES

1997 Contest - "Pass the Puck" or "Not in My Back Yard"

- BASIC OBJECTIVE:

have less stuff on

your side of the table at the end of a 30 second round. You are pitted

against a single opposing robot.

- ROBOT CONTROL happens via four

electrical and two pneumatic switches. Your optional one-man pit crew

can help you drive.

- THE TABLE: Click here for an animated GIF of the table.

- SCORING: Balls are worth 1pt., pucks

are worth 3pts., your robot is worth 10pts. A "multiplier shelf" on

either end of the table doubles the value of anything on top of it.

THE DESIGN

PROCESS

Or "Reckon it'll work?"

PRELIMINARY GOALS:

- Reliability

- Versatility - this is in case one part of the machine ends up

not working correctly, or if a sudden change of strategy is needed

during a particular round.

- Ease of driving (nervousness is a factor)

FUNCTIONAL REQUIREMENTS:

- Be able to obtain the group of

nine balls from the multiplier shelf

- Be able to launch balls across the court to the opposing robot's

multiplier shelf

- Be mobile to increase versatility, point scoring potential

- Be able to push balls off the central ridge so it's easy to get

a few points if necessary and defend against intrusion by other robots.

RESULTANT DESIGN PARAMETERS:

- Ball shooter: use quickly

rotating cylinders powered by polaroid

motors, like a tennis ball shooter. Spring-launching all nine at once

is problematic because it could hit and damage other robot, or else it

could hit opposing robot's tether

- Ball getter: tongs? (later: tongs are problematic. Switch to

rubber one-way ball valve)

- Ball pusher: pneumatic? (later: specific ball pusher

scrapped. Instead, ball getter arm gets used for defense and ball

pushing)

- Put this thing on wheels.

Benefits:

- Very difficult to defend against unless opponent

designs robot specifically to defend against mine. Not really a viable

option

for anybody

- A real crowd pleaser! Imagine balls launching across the

field!

Problems:

- Ball shooter is difficult to implement, may not be reliable,

motors may not be powerful enough

- Ball acquisition may not be reliable

- Tight spaces: tricky to deal with all the angles and small

spaces that this robot needs.

NUMBER CRUNCHING AND VISUALIZATION:

|

After the

preliminary thought experiments, I did some number

crunching to see if this design would work (actually, I did some as I

came up with the design to make sure what I was thinking was going to

work) To the left is the spreadsheet I used to do proof of concept for

the design. Using this sheet I was chose which motor to use, an order

of magnitude expectation of how much time there should be between ball

firings. At this point, I imagined I would be able to allow balls to

roll into the shooter one at a time. Real-world testing without such a

mechanism in place showed this to be not a particularly big

problem, as the cylinders in general had enough stored energy to be

able to shoot several balls in quick succession.

|

| To the right is

a

to-scale sketch of what I intended my robot to look like. In fact, I

used over seventy pages in my notebook for calculations, idea notes,

scale drawings, and machining plans for this robot. Click here and here for some decently large pictures

(~150k) of other ideas I considered before settling on the ball

shooter idea. |

|

THE

BUILDING

PROCESS

Or "Whoops, it would have been optimal

had that occurred to me prior to the inception of cutting."

I learned pretty quickly that it's a

big help to draw as much as

you can up before coming to lab. Otherwise, you end up sitting in lab,

confused by trying to think of too many design parameters at once. On

the other side of the coin, the building process is a continual

process of design, build, and re-design, so you do need to come in

and play with the motors and the materials to get a feel for them. You

certainly can't design your whole robot and then just build it. If you

are, chances are your robot is too simple. Usually it takes a little

experimentation to get a tricky mechanism to work.

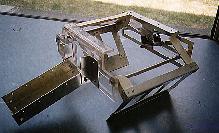

| The priority for

construction I used was to start with the most fail-prone, doubtful

mechanism first. If I found there was no chance of it working after I

built a prototype, I would have committed as little time as possible

to it. To the right is a picture of the test ball shooter I built. Via

spreadsheet calculations, I was able to conclude that the two polaroid

motors were the way to go. Its design allowed for varying the distance

between the two cylinders, which proved to be an invaluable means to

with reasonable precision fire the balls the distance I wanted - to

the opponent's shelf. The axles are welding rod, and the bearings are

made of delrin lubricated with teflon. Happily, this mechanism worked

like a charm. I added the teflon lubrication to the bearings after I

burned out one of the motors. This was one of the big risks in this

design: I was sending 13.8 volts through motors that were designed for

6 volts, and they could burn out at any time. In preparation for the

contest, I did wire up two backup motors in case of another

burnout. But adding the teflon proved to be sufficient to avert burning

out these motors. |

|

|

The next stage

was to

fulfill the design parameter of funneling the nine balls into the

shooter. After finishing the most critical and doubtful mechanism, I

started work on the ball acquiring mechanism. After about a week

working on the mechanism to the left, which was supposed to pick up

balls using a tong-like movement, I realized the importance of

cardboard mockups. With this mechanism, the balls went all over the

place. Only after much consternation did I abandon this mechanism. I

had painstakenly milled out holes in the lexan and aluminum to reduce

weight in the frame, did a complex riveting operation to save aluminum

on the tongs, and had even come up with an ingenious geometrical

mechanism to insure the two tongs kept the same angle with respect to

each other as they pivoted. |

Mostly, I regretted losing the high-tech, intricate appearance these

tongs would have given my robot. As a result my robot appeared much

less well made than it could have. Essentially, I felt like this

design cheated me out of the opportunity to really show off my

machining skills. But such is the way of engineering. Besides, I knew

that even though I was losing something by not having these tongs, I

was in fact doing better engineering by not holding steadfast to a

counterproductive idea. A lesser engineer would have stayed with the

faulty mechanism for fear of making something even worse or running

out of time. As this contest has demonstrated to me in retrospect many

times over, nothing ventured, nothing gained. The decision paid off.

As I contemplated, it eventually

became clear to me that I would

have no choice but to take inspiration from past contests and build a

"one-way valve." I had earlier mistakenly discounted the idea,

thinking that a one way valve could only be effective for lifting very

lightweight objects, such as ping-pong balls. I find this sort of

thinking -- just coming to a conclusion without really thinking

something through -- is an obstacle for any engineer who is trying to

come up with an innovative solution to a difficult problem. For this

reason, I prefer to work in small teams. In general the multiplicity

of heads will do an excellent job of eliminating such narrow headed

thinking.

To explain the mechanism here, the

rubber bands "press" through

the rack of nine balls and then restrict the balls from falling back

through. Hence it is a simple and elegant mechanism for getting a

group of balls. This mechanism was far superior because it was

mechanically far simpler, faster at getting the balls, and less prone

to failure. That it didn't look as cool continued to bother me, but

what recourse did I have? This was real engineering, and

what great bridges, yea, even Missions

to Mars, are made

from.

| Here, the

prototype

ball collector is attached to a yet-to-be completed chassis. Once the

balls are in the collector, the arm pivots upward and funnels the

balls into the channel that leads to the twin firing cylinders. To

handle the problem of balls getting clogged in the funnel, I could

simply jostle the arm back and forth and they would fall through. I

was worried that this would be a problem, but that method turned out

to work just fine. Besides, the firing motors needed time to

re-spin-up between groups of balls. |

|

|

|

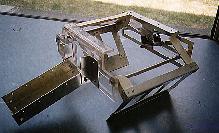

Finishing the

robot

was essentially an excercise of throwing together two wheels (about an

hour of work when you're working in the beautiful, high-tech Papalardo

machine shop like we were), making a last-minute makeshift front two

wheels, and deciding in the end to scrap my pneumatic "ball pusher." I

already had an arm to push balls off the ridge, why did I need a

specialized pusher. This neglecting of the idea of using my arm as a

ball pusher was yet another example of the one-man tunnel-vision

syndrome. To the left are a side shot of the robot with its arm in the

collapsed state (to fit within the space constraints) and an isometric

view with the arm open. |

Make no mistake about it, though. When

the robot was visually

finished, I was far from ready for the contest. One of my big

advantages was that my robot was done a week early. Seppo

Helava, great guy that he is, sacrificed his time to come in and

practice driving my contraption on several occasions. This made a huge

difference. Lots of practice was his idea. It was a good one. The

first time we tried to drive it the robot was all over the

place. There were funny noises coming from the ball shooters (teflon

fixed that), and even one of the motors burned out, as I mentioned

above.

At one point I came to the realization

that I had set up my

robot controls wrong for me: I had given my left hand the brainless

job of running the ball shooter, and my right hand the delicate job of

manuevering the arm. And that was just plain dumb: What had I been

practicing for while I was playing Nintendo all that time? This

contest, of course. And everybody knows it's your right hand gets the

boring job of pushing buttons, and your left hand is the one that

knows how to delicately manuever things. This was especially the case

with Mario 64's proportional movement. Thanks to Keith Breinlinger,

the head T.A. of the contest, we got proportional movement on two

channels, which was exactly what I needed for the arm. So I improved

the human interface to my robot as well.

While Seppo was at classes I made

redundant parts and went through

and made my robot ship-shape. Come the day of the contest, I was

completely prepared, and my robot had been performing well enough that

I wasn't worried about it failing. This, I now know, is a good feeling

to have when entering a contest.

THE

CONTEST

Or "Wow!"

The Short Story:

2nd Place!!!!!

The Long Story:

Out of ten: Five parts design and

workmanship, three parts luck,

and two parts driving skill. I thank tremendously Seppo "sQuink"

Helava for some kick-ass driving, brain presence, mental support, and

awesome strategy ideas during the contest. He's just off to the right

of the picture above. You can see his right arm.

My strategy for handling potential

nervousness was to concentrate

on the fun I was going to have. I broke it down to: each contest is

just a couple of robots, and I'm just curious what's going to happen,

see if my robot was in fact a good design. It seemed to work pretty

well. In general, we had no mental mess-ups, the robot worked perfectly

every time (what bliss!), and we worked well as a team.

Some of the highlights:

- Round 4, against robot #77, a

robot that started on a platform

and drove over to our side to obstruct our robot: After opting not to

take a defensive stance and instead setting ourselves up right in

front of the set of nine balls, we launched the group and then

proceeded to catch him off guard. He drove his robot to the second set

of nine, expecting that to be our next goal and intending to stop us,

and we proceeded to use our arm to instead knock balls off the

ridge. After getting a few more points, we then just lowered the arm

and pinned his robot, stopping his robot from getting onto the

multiplier shelf.

- Round 5, against robot #177, another platformer: This was

great. We set up right in front of the ridge and then just lowered our

arm down in front of him. Subsequently, he found himself eited off his

platform by the force of our arm and consequently a dead duck. At the

crowd's behest, we went back and launched a few balls for effect.

- Round 6, against robot #150, Steve Paik: Yet another platformer

to deny. This one was close, because his robot got under the front of

ours, and for awhile it looked like the balls weren't going to be able

to fall into the shooter. Miraculously, they did, and the crowd got to

see some high lobs (instead of low, fast throws). This turned out to

be somewhat advantageous, because it meant that almost every ball made

it onto the shelf.

- Round 7, against third place Aaron Winters: Using our ball

shooter, we spread balls across his multiplier shelf, and this

functionally disabled half of his scoring potential. His strategy was

to get all the balls off the ridge onto our side and then pull the 18

balls off of the multiplier shelf, but in order to get the balls off

the multiplier shelf, he needed the balls to be in perfect order and

have nothing in the way. We put stuff in the way.

- Round 8, last round, against Tim Zue: What can I say? I opted

for the defensive approach (try to knock him over as he tried to come

over). Unfortunately, Zue had probably the best implementation of a

platformer, having added walls to keep from being pushed off, and we

were unable to dislodge him. And because he had pushed a few balls in

the way, we weren't able to get any balls from the multiplier

shelf. This was the aggressive approach; who knows if the squeamish

(go directly for the nine balls) would have been effective?

CONCLUSIONS

Or, "Sawyer's Secrets for Success"

Ya want 'em? I got 'em.

- Reliability, reliability,

reliability. This means when it's the

last week before the competition, you don't have the time to add one

more feature. Turns out, when you think you are done, you still have

lots more to do. Even though I was done with my robot a week "ahead of

time," I still found I needed to spend all of that week in lab working

out little kinks and making backup parts where appropriate.

- If it seems like you are going to be done way ahead of time, it

probably means you are going to just make it in time.

- You know, it's not that big of a deal. Actually, what you're in

a contest for is to experiment. It's where learning comes from. You're

in this contest to see if your robot was actually a good design. If it

wasn't, if things went well you will be able to identify what you did

wrong. Usually it was a violation of one of the above tenets. If

you're just in it to pamper your resume, you're probably in it for the

wrong reason.

- Risk stuff. But know what your risk is. Engineering is coming

across a risk, thinking, "oh shit, I have no idea how I am going to

make this work," and then through this small level of anxiety

proceeding to think through as much as possible to convince yourself

it actually will or come up with solutions to the problem that enable

it. As Prof. Blanco says, inspiration often accompanies

desperation. But don't forget to remain a skeptic, as well.

- Don't become a worry wart. If you start worrying about every

little thing, you will start to look like NASA does now. Bloated and

slow. Too scared to try anything.

- Uhh. . . and lastly, as Prof. Slocum says, it's always to your

benefit to have a "big box of legos" -- lots of engineering tricks and

experience. If yours is big, you know it and you are probably

continuing to expand it, and if it isn't, there's not much substitute.

Ya can't really

get around it.

Well heck, thanks for reading this

page. I hope you learned

something from it, and I hope you enjoyed it. I had a blast.

Last Updated 9/26/97.