Kitfox Model IV Construction Timeline

This

is basically the rough timeline of construction. It also contains entries

from my Dad's logbook. Logbook excerpts will appear in quotes and italics.

| 4/10/93

- |

Trip

to Idaho to pick up Kitfox Fuselage Kit

"Started

at 12 noon head for Portland thru Columbia River Gorge to Idaho

to p/u the frame." |

| |

|

|

This is

truly the start of the project. My Dad decided to go down to

Idaho to pick up the first kit. This is the heading off on the

beginning of a 10 year adventure.

Here we

are with our old Toyota van packed and ready for the trip to

Skystar in Idaho to pick up the fuselage frame kit.

|

|

|

| |

We towed

the trailer behind us to carry the fuselage frame. Since it

was going to be a several day trip, we also build a rooftop

camper that mounted to the top of the van.

|

| 4/11/93

- |

Car

water pump breaks en route to SkyStar

"Water

pump at van broke (shaft). Stuck at Exit #168 at Hwy 84." |

| |

|

|

|

|

Unfortunately,

one day into our trip, the water pump on the van broke and we

had to be towed into the nearest town to get replacement parts.

This put a 30 hour delay into our trip, but considering that the

project took 10 years, this isn't that bad in the grand scheme

of things. |

| 4/12/93

- |

Picked

up Fuselage Kit at SkyStar Aircraft facility in Idaho

"Started

visit at 9:30 am. (3) Seperate buildings. 90 employees, sales,

customer support, engineering (head by Frank Miller), R&D,

wood shop, welding shop, raw mat'l cutting, shipping, parts packaging,

tech/manual writing. Operation is quite organized..." |

| |

|

|

We finally

arrive at the SkyStar factory and take a grand tour of the facility.

Dad even went flying in the 582 Mk IV.

The plant

was an impressive place with a lot of good facilities. It was

my and my brother's first tour of an actual small airplane construction

facility. Get a load of how young all of us were back then.

|

|

|

| |

|

|

Here

is Dad sealing the deal which would start the 10 year

construction project. He's shaking hands with the president

of SkyStar, Phil Reed. The funny thing is the that Phil

Reed is actually from Mercer Island as well. My little

brother actually had classes with his son. |

| |

|

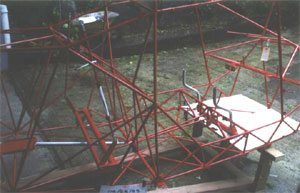

|

After

chatting with everybody, we had to load up the frame for

the long trip back home. You can get an idea for the size

of the entire plane from this photo. The frame comes prewelded

and powder coated. |

|

|

| 4/25/93

- |

Installed

control stick and seat

|

| |

|

|

"Temporarily

pinned all ctl. aileron and flaps together. All operating

smoothly except flap bolt is hitting the frame"

Here

a right side view of the fuselage with the control sticks

and seat installed.

|

|

|

| |

|

|

Its

starting to look like a plane. Here's me and Tim sitting

in the cockpit and playing with the control sticks. Its

fun to make plane noises and pretend you're flying, when

you're only 13, you can fool yourself into believing anything. |

| 6/29/93

- |

Pick

up Wing Kit

"At

SkyStar, met up with Phil Reed, Morris and Harry w/ Chris

Jon, Tim and Mom's help, wrapped parts up w/ foam protective

wrapper. Slided long pieces into motor home thru rear

bathroom window." |

| |

|

|

Here's

another trip to the Skystar plant to pick up the next

kit. I'm starting to see why they call it a Kitfox.

Each kit by itself isn't very expensive, but you've

got to buy a couple of them. Here's Dad sliding one

of the flaperons (aileron + flap) through the bathroom

window of the motorhome.

|

|

|

| |

This

time, we took our old motor home down to plant. We kind

of made a vacation out of the trip and stopped to visit

Yellowstone park on the way home.

The

wing kit consists of the flaperons, wing ribs, wing spars,

and pretty much every thing you need to build the wings

themselves minus the covering.

|

|

| 10/1/93

- |

Aladize

main wing spars |

| |

|

|

We needed

to aladize the main wing spars. This is basically a process

which prevents the aluminum from reacting with the oxygen in

the air and forming an oxide on the wing spar.

|

|

|

| |

| 10/31/93

- |

Finish

Wing Contruction

|

| |

|

|

"Finished

setup and drill and cleco left wing together. First trail flaperon.

It worked good!!"

Here's Gid

working on the wing replacing the clecos with rivets to mount

the bracket which holds the wing struts.

|

|

|

| |

|

|

Here's

me helping out as well on the fuselage frame. |

| |

|

|

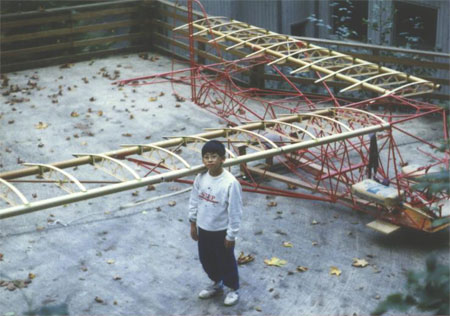

Its

starting to really look like a plane now!

Jon

has to hold up one side of the plane with his shoulder to keep

it from tipping over like a cow.

|

|

|

| 1/16/94

- |

Mount

wheels and landing gear

"With

Jon's help, filled hydraulic lines with jack petroleum base hydraulic

fluid using syringe and tubing from the bottom up starting from

the left side then from the right side. Took about 40 cc or so.

Tried it on the slope driveway. Worked pretty good. Now it needs

control springs and chain to steer the tail wheel." |

| |

|

|

|

|

Here the

plane about 250 hours into the project. Both wings are mounted

and the landing gear is on. The brakes even work now as well.

Also performed

some preliminary weight and balance calcs. with the wings folded.

|

| 6/15/94

- |

Pick

up firewall forward kit |

| |

|

|

This time,

we didn't go down to Idaho and pick up the next kit directly

from SkyStar. Instead, he had it shipped up.

Here's Jon

working mounting the bracket which is used to align the false

ribs on the wing. He looks pretty intent on his task. I hope

he knows what he's doing.

|

|

|

| |

| 6/??/94

- |

Exhibit

plane at EAA show at Museum of Flight |

| |

|

|

|

|

Here's

Dad with his exhibit of the Kitfox. There were a lot of other

partially finished homebuilt planes on exhibit that day. |

| |

| |

|

|

Here's

the plane with both wings and moving control surfaces. We loaded

it onto the trailer and towed it with the motor home down to

the Museum of Flight for the show.

|

|

|

5

Year Break to Build House

| 6/??/00

- |

Continue

construction after completing house

"Started

construction again after finishing the house." |

| 5/20/01

- |

Mount

float assembly to plane

"Put

in all bolts to attach float assembly to airplane." |

| |

|

|

|

|

Here's

some of the early work on the float struts that Dad built to mount

to floats to the plane. With the floats on, we could take it down

to the water and see how stable it is with floats attached. |

| |

| 8/27/01

- |

Engine

bracket mounted and tested |

| |

|

|

Here's the

engine bracket mounted to the plane as it will be in flight.

The weights are used to simulate the weight of the actual engine

to see how the plane sits with the engine in.

|

|

|

| |

| 8/28/01

- |

Test

assembled frame on water

"Got

it on the water. Able to unfolt and setup wing and pinned w/ one

person by myself.." |

| |

|

|

|

|

And

the plane floats! Here we are at the Mercer Island boat launch.

Dad was able to put the plane in the water and unfold the wings

by himself. The plane seemed to work fine and was stable in the

waves. |

| 8/22/02

- |

Covering

wings

"Cut

leading edge to scallop shape using a template. Go over the whole

thing using 225 F iron. Heat shrink bottom wings using 250 F for

both wings." |

| |

|

|

Here's our

neighbor, Jay, coming over to help with the covering of the

wings. He's helping with the application of the poly-tac to

the ribs. This is the material that makes the fabric stick to

the ribs.

|

|

|

| |

| 8/23/02

- |

Stitching

the wing coverings

"Jon,

Jaye, and Judy helped to apply poly-tac to finish the other top

wing." |

| |

|

|

|

|

The fabric

covering of the wings need to be stiched and laced to the ribs.

This is a very long and tedious task, so Mom is helping out

as well.

|

| 9/16/02

- |

Finish

taping fuselage

"Picked

up all taping on fuselage, 3 inspection rings, three round drains

and 1 seaplane drain on the vertical stab." |

| |

|

|

Here's the

fuselage on its side so that the fabric and taping could be

completed.

|

|

|

| |

| 11/8/02

- |

Painting

empannage

"Painted

rudder, fuselage, horizontal stab, and vertical fin and elevator." |

| |

|

|

|

|

Dad

wanted to have a sunburst paint job. He spent a lot of time getting

the paint scheme just right. It looks really good on the finished

product. Here's just the rear control surfaces painted. |

| 11/9/02

- |

More

painting

"Painted

all hard surfaces w/ red enamel, wing tips (2), (4) flaperon hinges,

inspection covers (6). Took in paint booth, re-hung florecent

lights and stored all tubings and plastic sheets in storage shed." |

| |

|

|

The painting

is a very nasty process. In order to contain all the fumes and

overspray, Dad built a paint booth in the garage. This was thermally

regulated and isolated from the outside. This kept all the paint

spray inside and Mom happy.

|

|

|

| |

|

|

|

|

Here

all the used cans of paint and other chemicals required to do

the paint job. |

| 11/16/02

- |

Finish

painting and start to install floats

"Btrought

assembled float to under plane. Using 2 9 foot long steel pipe,

raised palne to 48" or so high on front fitting." |

| |

|

|

Doesn't

the paint job look nice? Now that its all painted and reassembled,

the floats need to be mounted back on. We used some steel pipes

at the cg of the plane and two engine hoists to pick it up.

|

|

|

| |

|

|

|

|

Here's

the plane all covered, painted, and assembled on the trailer.

Its almost ready to fly except for... |

| 12/5/02

- |

Engine

kit arrives

"Picked

up engine from Overnite Transportation." |

| |

|

|

The last

kit before the plane is airworthy. The engine is a 2 cylinder,

4-stroke, 65 Hp Rotax engine.

|

|

|

| |

| 12/6/02

- |

Hoist

engine onto engine mount

"Hoisted

engine into place. Bolted on prop." |

| |

|

|

|

|

Here's

the engine installed on the engine mount. There was a lot more

work to connect it to the fuel tanks and prepare it for starting

up for the first time. |

| 12/30/02

- |

Engine

break-in

"Engine

break in all done in a little over an hour. All boys helped. Chris

w/ computer as stop watch. Monitor temp on data acquisition ssytem.

Jon shot video and monitor engine condition. Tim as fire watch

and spotted loose air bleed clamp to fuel pump." |

| |

|

|

Over

Christmas break, we broke in the engine. Its a pretty long process

where you run the engine at different RPMs for different amounts

of time. We had everybody outside working on it. We had to tie

the plane to the tree so that it wouldn't fly away on the higher

RPM spots. |

|

|

|

|

|

| 2/1/03

- |

Complete

instrument panel

"G-meter

and compass arrived. Rotate housing for compass to make it mount

on the ceiling." |

| |

|

|

|

|

The

last thing to do was to instrument the plane. Dad built the instrument

panel from scratch and custom installed all the instruments. |

| 2/24/03

- |

Obtain

Airworthiness Certificate

"Charlie

showed up and gone thru w/ inspection and paperwork. Got special

airwirthiness certification and operating limitation. Ready to

fly. Finally." |

| 3/1/03

- |

FIRST

FLIGHT!!!

"1st

flight at 4:00pm or so. 3 flights to 1800 ft or so over Lake of

Washington w/ Judy, Chris, Jon and Phil. Engine running good,

everything in the greed. Flown at 60-75 mph. Landing at 45-50

w/ some power upon flare. Airplane was rock steady. Did shallow

5-10 degree bank turn. Right hand traffic wind from NW about 3

mph. Did a few 10-15 feet above water short hops." |

|

|