TriTrack FAQ

How are the vehicles attached to the track?

The TriTrack has several modes that it can operate under. Because the cars are externally specified in the open architecture concept they will all have the exact same interface with the tracks. There will be attachment points on the car that are separate from the main triangular track that will allow the empty cars to operate without a driver.

What about parking large numbers of these vehicles?

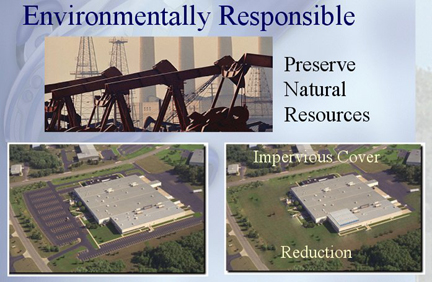

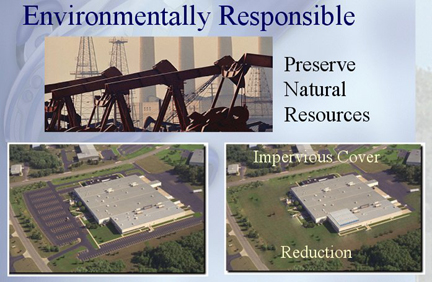

These same attachment points will provide a way to park the vehicles on their tails. The heavy battery pack will separate from the car and go into an automated charging queue. The car body without the battery pack is light enough to be parked on the roof of a building without over stressing the building structure. The tracks that move the car body shell to the roof are similar to the automated inventory systems that a lot of companies use. For example, the Motorola manufacturing plant in Fort Worth, Texas, has a totally automated inventory system on the front of their factory. The inventory stock is brought to the production floor in a completely automated manner. The only cost to the TriTrack design are some common and specified attachment points. This is not a minor point because parking the cars in a more compact manner opens up expensive real estate for better uses. This is a way to help justify some of the cost of the system by turning parking garage space into higher value real estate. What it offers to the public is they no longer have to hike in from acres of parking lot in the rain or heat or cold. An illustration of such a parking scheme and its effect on land use is shown below.

Could the TriTrack system be used to move freight around the urban area?

The parking concept ties into small package delivery via unmanned vehicles. It would allow twice a day mail delivery within regions at very low cost. The vehicle for freight would be exactly the same on the outside and would have to adhere to the weight specification.

Could the TriTrack system accommodate disabled persons?

Shown below is an illustration of the Americans with Disabilities Act version. Because the car belongs to the rider it can be made to suit the needs and the tastes of the owner. I am sensitive to the needs of persons who find themselves in a wheel chair. The TriTrack would allow persons with disabilities equal access to where they want to go.

When you go fast what holds the car on the track?

The TriTrack is a ground effects vehicle and some of its efficiency comes from the fact that at high speed there is sufficient wind force to lift the body. There is an air inlet control valve where the car body meets the track. That adjustable duct keeps the bulk of the weight of the vehicle raised off the wheels, similar to an air hockey puck. The TriTrack track is held on all three sides by 6 steel wheels. These wheels control the trajectory of the vehicle. At 180 miles per hour (290 kph) you don't need to use maglev levitation to raise the weight of the car the air will lift it. The air that is allowed to go between the car and the track will be adjusted dynamically to bias the wheels and maintain mechanical stability. The car body reaches around the track leaving a small gap underneath the track and cannot come off until it gets to the end of the track. Even if the wheels fall off and the motor burns up the car body itself will not come off the track.

What happens in the event of a catastrophic failure?

Even if a crane crashes into the track and takes out a section of track the cars will be able to stop because they grip all three sides of the track. Present cars have to rely on traction between the rubber tires and the pavement. In icy conditions all bets are off in your car and you spin off the road. The TriTrack will have an emergency brake system that applies brake pads directly onto the track on three sides. This will allow the car to stop as fast as the human bodies inside can endure. The cars tailgate each other at a distance of 28 feet and are electronically linked within 30 milliseconds of an emergency event. Each car further back in the chain will have a longer stopping distance till the car in the very back will gently slow to a stop. Taking the human reaction time out of the equation makes this a much safer system. Other than in an emergency the cars never use the brakes while on the track. The linear generator at the down-ramp slows the car down and reclaims all but about 4% of the energy used to accelerate the car from 40 miles per hour (64 kph) to 180 miles per hour. Brakes just take energy and produce worthless waste heat. There are no stops or merges in the system.

How does the TriTrack vehicle compare to the F300 Life-Jet Mercedes Benz three-wheeled vehicle?

This three-wheeled motorcycle looks cool but the aerodynamic drag coefficient of the body is not very good. One of my biggest challenges is countering misconceptions about aerodynamics. Edges and bumps are not very good shapes for efficiency they just look cool. Racecars create a tremendous amount of down force that they need for tire traction. Most people associate racecar shapes with aerodynamics and it is an incorrect assumption. If you want to see a shape that is aerodynamically efficient look at a bird's body in flight. The TriTrack car body is the shape of a class "C" airship. This was empirically studied in 1929 by the US government. Aerodynamics is not new. The drag coefficient of the TriTrack body is .09 as compared to a standard sedan of about .31 for a 1995 Mercury Sable.

How big is the car?

The diameter of the car is 1.2 meters. This is a little cozy for most people. If a guy is riding the car with his girlfriend he would probably sit beside his girlfriend. If he is riding with someone less familiar he would probably sit in the front seat and the passenger would sit in the back. The front seat folds down and you step on the folded down portion to get into the back seat. It is a little tricky to get in the back seat but many two-door cars have a similar problem. The car has no frame. The body shell provides the strength of the vehicle. If I cut too much body away for doors then I lose the strength of the protective shell. A small frontal area is required to reduce the energy consumption. Frontal area multiplies with the drag coefficient in the equation for total air drag. If the frontal area is increased, then the energy waste gets worse.

What are the relative merits of being suspended from above versus having the body surround the track?

The three sided track allows pitch yaw and roll to be controlled so we don't have to suspend the cars from an even higher guideway. The whole trick to guiding the car smoothly is in how the track is manufactured. The TriTracker takes into account the bowing and shrinkage that the concrete will be doing in the manufacturing process. When the track is finished it will be very straight and smooth even though the initial extruded shape will be curved in several ways. This smooth track is the basis for keeping the car on top of the rail. In contrast if you have ever been to a ski lift the last thing the gondola does as it comes into the station is whack the boards that slow down the swinging from the overhead support. Steadying the swinging takes time. If you build a track from above, the poles will be taller and will have to be much stronger to take the vertical load plus the torque caused by the offset. Beam strength versus length is not linear. If a beam is a little bit taller it requires a lot more strength to maintain the same rigidity. It is hard to beat a straight pole with no side load. The cost of the track construction is significant and anything we can do to simplify the track will ease the burden on the taxpayer.

Could a track be placed along side the interstate and take people downtown while the track grid system is being built?

You have to think big for this to work. I have no intention of putting in a 10 mile track. That would be fairly worthless. The important part of this system is the TriTracker machine that produces track at 3 miles per hour. There is a standard truck (picture at left) that would have a standard aluminum extrusion machine mounted on it that will extrude a hollow shell at 3 miles per hour. The rollers on the TriTracker will roll the extrusion to shape and the track will be made in place. There are several patent claims to this portion of the design but the idea is to revolutionize the road building process. As with any automated process the workers will not be leaning on their shovels.

The track is formed quickly and temporary supports are placed in the wake of this machine. Because this is a weight-limited car the supports are not nearly as massive as you might imagine. They are not much more than a cardboard tube placed over a hole and filled with concrete. There is no ground preparation required other than to drill a hole with a normal tractor and auger. The hollow extrusion is drilled from underneath and high strength concrete is pumped and purged into the track. The rollers create a shape such that when the concrete finishes setting up and shrinking the track is the correct shape. This requires new thinking about the cost and time to build a complete grid system in an entire city.

Austin, Texas, as an example, would have 30 sets of tracks going East/West and 30 sets of track going North/South. At 3 miles per hour that is not a lot of construction time. As with all the other ultra light guide way systems the rails go down existing underutilized right-of-way. The easy way to envision where the tracks will go is where cable TV goes now. The very center of the TriTrack is hollow and that is where TV cable and power lines will now go allowing the current mess of drooping wires to be organized and hidden from view. The power company will have a real interest in seeing the system go in because this is a way to significantly increase their market. They own the poles and have dominion over the right-of-ways and they would be able to actually implement the track grid without much commotion.

Can there be a slower set of tracks for shorter trips?

It is very important to maintain a uniform speed on the system. Today traffic flows by accident. In order to have an organized transportation system you will need to keep everyone moving along. It only takes one person going 30 mph on a highway to bring the current system to a literal halt. The same is true of any system where there will be someone in front of you. All the cars need to go the same speed.

There are design tweaks that can be made if the system is uniform. Much of engine design goes into making broad power curves for engines. This adaptability costs in both performance and in efficiency. This is a different discussion about present gasoline cars but it would be better if everyone went the same speed if they are going to share the same road. Why would you want to go slow when you don't have to? The energy that is put into the car to make it go fast is reclaimed on the other end of the track (minus about 4%). The up-ramp is powered by the electric power grid and a linear motor accelerates the vehicle from 40 miles per hour to 180 miles per hour (290 kph). When the car gets to the other end of the track there is a linear generator that reclaims the energy that was added to the mass on the up-ramp. This pulse of power is taken right into the battery packs that are in the charging queue just under the track.

The only energy associated with going fast is the rolling friction of the steel wheels on aluminum that is partially floating via ground effects air cushion and the aerodynamic drag of the car. Much design went into making this vehicle low drag. The drag coefficient is .09 for this body shape and the frontal area is much smaller than a standard sedan (.31 for a 1995 Mercury Sable compared to .09) so the energy to go fast is less than you might imagine. For comparison commercial 747 airplanes cruise at 565 miles per hour and Indy cars go 220 miles per hour. 180 is three miles per minute so if you live 9 miles South of work your commute is 3 minutes. Nine miles on a "light" rail would be 28.5 minutes (e.g. Portland's Metropolitan Area Express - MAX light rail system).

Why is the weight limited on the TriTrack?

The TriTrack does not replace any existing surface roads. It adds to the capacity. Trucks and heavy equipment will still need to be on the asphalt. The idea behind ultra light rail is that you only take as much vehicle as is required. You don't have to transport the battery packs up on the rail. You don't have to overbuild the track to take on overweight vehicles. The present highways are the ultimate in over design. We all pay the price via taxes for the over design of the current highway system. The poor bridge designer has to design a bridge that can take massive trucks carrying oversized and overweight loads. The massive amount of steel and concrete required to hold up 1 oversized vehicle out of 20,000 is what we pay for. The TriTrack actually weighs the car as it attempts to get on the track. If the car is overweight it has to stay on the surface street. This keeps the size of the structure from compounding. This is what keeps the cost and visual obstruction down.

How are vehicle merges handled?

There are no merges and no stops. The car gets on the end of a track and it gets off at the other end of that track. The tracks are in groups. Each adjacent track is twice as long as its neighbor(e.g. 1/2 mile, 1 mile, 2 miles, 4 miles) You pick how far you want to go when you get on a track of that length. Keeping the tracks generally straight allows the supports to be smaller and the ride more boring. This is the opposite of a roller coaster. I want the trip to be very smooth and uneventful. At high speed if you make tight radius turns you will be thrown around inside the car and that would not be good. The tracks should be due North and due East and in a regular organized pattern.

Would the vehicles have to be inspected before being allowed to use the high speed track?The entire system will be linked with wireless communication. This technology is very inexpensive already and it will be very redundant. The car will actually weigh itself before it approaches the track. The riders will be made aware that the car is overweight and will need to shed some weight before being allowed on the system. The car will actually run a long way on the street system at 40 mph. I have a golf cart on my pecan farm that I use to water and spray the trees. It is great for the tree farm with hundreds of starts and stops a day but it runs all day on a charge on bumpy dirt/turf paths. The TriTrack car will have a much lower rolling resistance on pavement than a golf cart on turf so it will go a long way if needed and you can always pick up battery packs as you go along if you do happen to deplete one. The car is designed to carry 4 85th percentile (by weight) people. If you have four big men going to lunch you should probably take two cars. This is a little rude but that is the price you pay for having a specification. It is better to have a known and published weight limit than to over-build the entire infrastructure.

How is the vehicle steered when using the surface street system?

This illustration shows the 1888 tricycle Benz car. Before cars became so complicated and heavy they were three wheeled and they were steered by a tiller. The steering mechanism for the TriTrack is a tiller in the driver's left hand. This allows more space inside the car and provides more power from the driver to turn the wheels. I probably don't need to go into a long discussion about the steering wheel versus a lighter weight approach because it takes some getting used to. If you consider the muscle groups that are used to rotate a steering wheel they are the really weak ones and they are at a mechanical disadvantage. They are the same muscles you use to open a door for a lady. They do not compare with the much larger muscles used in pushing or pulling.

Since the car is light weight and the tire tread width is narrow there is no need for power steering and all the mechanical advantage that goes into a steering column/pitman arm power assisted arrangement. This is one of those weight compounding issues with cars. There is a lot of iron that goes into a car's steering gear box and steering column not to mention the injuries that steering wheels cause the driver. I want to avoid the steering wheel discussion on the page and I can throw in a steering column if it bothers anyone but after you get used to the idea it is lighter and more efficient. The 1888 Benz car ties in well with the 2003 Benz car that has come full circle to three wheels.

Won't the entry and exit ramps have to be quite long to allow for acceleration/deceleration to/from 180 mph?The ramps will be long enough to accelerate the car to speed without making people motion sick. This may take some real world tests to determine. When you stop in your car you can produce a couple of Gs for a few seconds. I will start with the same G force that people are used to. This will determine the length of the linear motor section. From a cost standpoint the shorter the better for the linear motor. From a comfort standpoint the longer the better so a compromise will need to be reached. One G will accelerate you at 32 feet per second per second. It doesn't take long to go from 40 to 180 at one G. The answer that we will get from field testing will be what is an acceptable amount for most people. If you have ever been to Six Flags over Texas there is a ride there that launches you from the station at amazing acceleration. It is a real kick in the pants. Our system would be something less than that. The system doesn't accommodate every transportation need. The surface streets are untouched in this concept and anyone who doesn't want to accelerate too quickly can simply go in their old car or truck.

What would happen if a large number of vehicles all head for the same exit at the same time?

When the cars exit they will need to fan out like they do when approaching a set of toll booths on a turnpike. When the cars come off the track they will go from single file to more lanes on the surface street. This will allow more than a few feet of following distance. The roads won't be as crowded as they are now because each track in the system can carry 9,000 passengers per hour. In an area like Austin the plan is to put in 240 tracks or 2,160,000 people each hour. It will take a while for the population to catch up to that capacity considering the surface streets are still taking their 100 percent capacity. The need to tailgate won't come until years from now but the capacity will be there when it is needed.

Can TriTrack be deployed in cities that are not flat and have significant barriers to travel?

Texas is generally a boring and flat place but the beginning seeds of the triangular track concept was based on a beautiful bluff that overlooked the Lower Colorado River. (Does not connect with the Colorado River) I was looking to buy some land on which to build my eventual retirement home and I found a rare untouched piece of land half way between Austin and Houston that was more like Colorado in terrain. I was researching what it would take to build a house on that piece of overlooked, preserved nature. When I looked into the damage that I was going to have to do to the land to get a house up on the bluff I was disappointed. Between getting a road up a steep hill and having the power company do their damage the best parts of the natural setting were going to be destroyed. I was toying with the idea of making a track that could climb the hill without switchbacks that would not need to kill all the trees in its path. The TriTrack track came from my desire to get to that piece of land. As it turns out a developer came in at the last minute and bought it out from under me and ended up chopping down the trees anyway.

The TriTrack car grips the track on all three sides. It can go as steep as you want to go, including vertical. It would be great for a ski lift because it is lower impact on the land than most lift systems.When a fighter jet turns on the terrain following radar control it makes something akin to how the tracks will be in a hilly place. The height above the surface would be averaged as much as practical to maintain a smoother ride. The TriTracker will shape the track to whatever bend is required but for the sake of the passengers it is a good idea to keep them going generally straight. At 180 mph you don't want to be turning too sharply. In order to maintain a constant grade, current roads curve more than they would if they didn't have to keep the grade low. The TriTrack could certainly go through tunnels and the fact that the cars are a specified shape the tunnels would be much smaller thus cheaper to dig. I toyed with the idea of a total tunnel system and gave up on the idea. I do think it is important to create new planes for the next mode of transportation, either higher or lower.

What effect would snow and ice have on the operation of the TriTrack system?

Here are a few ideas on what to do about snow. In Austin it is totally not an issue. It snows here about once every two or three years. One thought is to run the electric power lines through the very middle of the track to clean up the visual mess of drooping wires that we have come to turn a blind eye to. In putting the power lines down the middle there is a certain amount of electromagnetic inefficiency in doing that. This inefficiency would result in some amount of heat being "wasted" in warming the track. The biggest reason why power companies don't want to burry the power cables is this energy loss into the surrounding ground or, in our case, the track as compared to air.It would be easy to provide heaters to the track to melt snow if necessary. It also might be possible to spray deicing chemicals on the track like they do airplane wings but you have me out of my element when it comes to ice. The triangle is turned with the flat side down so that rain and most snow and small objects will fall off. The front of the cars will certainly have sensors to detect something on the track and that would include snow or ice. How to remove the ice is another issue. I am not an expert on snow or ice so I don't have a good answer for ice but because the track has a relatively small surface area it is much more likely that it can be kept ice free than a paved road. The emergency brakes of the TriTrack can actually crush into the track if it needs to to stop. It does not rely on gravity to hold the wheels or brakes to the track. The track is contacted on all three sides of the track. I should probably show an image of the steel wheels on the track on the web page.

Last modified: January 23, 2015