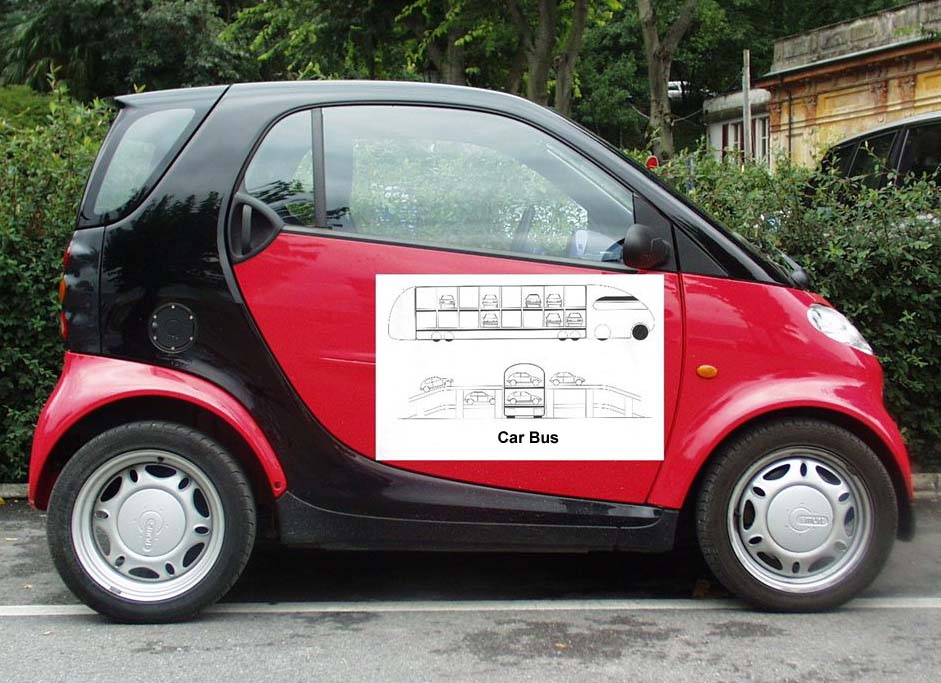

Car Bus Demonstrator

Presented at the Canadian Transportation Research Forum, Prince Edward Island, Canada,

June 4-7, 2000, by David Petrie, PETRIE TRANSIT CONSULTANTS

(updated April, 2005)

Abstract

The general solution to congestion in low-density urban areas will employ a Car Bus that transports the personal car at 80-mph on a barriered inside lane of the freeway. Stations will be located above the freeway at 4-7 mile intervals, accessed by ramps emanating from the outside lanes. Loading of occupied personal cars will be automated, 20 seconds elapsing from stop to restart of the Car Bus.

Since the Car Bus will be fuel cell powered and the motors of the transported cars will be OFF during the freeway portion of a typical commute, pollution due to fossil-fueled transport will be roughly halved. It is anticipated that Car Bus will capture 40-70% of all commuter-miles.

The capacity of this guideway will be so enormous that many high-performance freight trucks, equipped with automation kits, can be interwoven with Car Bus via entrance/exit gates.

The transporters will be automated with a computerized safety control sub-system, effectively adding up to 20 lanes of capacity on a single dedicated guideway, as 8’ long electric/hybrid microcars become available for general commuting and errands. The entrance of all cars and trucks into this unified transportation network will be computer-coordinated by GPS navigation feed into an automated cell-phone based communication system.

Since the transporters, microcars, stations, guideway, and central computer control should operate as an integrated system, a proof-of-concept demonstration should be built. This will also serve as a developmental tool to perfect operating software, proof-test hardware, establish patron use patterns, and gain operational experience.

Rudimentary manually-driven versions can be in operation while the more advanced version is under development. This early version will target transport of full-sized cars pending mass production of microcars; the latter destined to be the most numerous car in the 21st Century.

Congestion

In the modern low-density city—typical in the USA--only 3% of commuters use public transit. This is because the car/highway system over the past seventy years has shifted concentration of homes, workplaces, and shops from within walking distance of mass transit rail/bus stops to lower density suburbia. Such distributed development is not compatible with conventional mass transit. Stated more simply, people who want to use public transit must first get to the rail/bus station from their homes, then get from the station to their specific destinations. To walk the usual 1 - 3 miles distance to/from the stations is quite impractical for most commuters. As a result, 13 out of 14 commuters in the USA drive alone, giving rise to the term "SOV" (single occupant vehicle).

Mass production techniques have made the personal car affordable to almost every citizen. In the USA, there are now 1.08 cars per licensed driver, with many owning vehicles designed for specific purposes: vans/sport utility vehicles, pickup trucks, sport cars, and motorcycles.

We have now built a society based on the car/highway system from which there is no turning back. Car pooling is near impossible, because few commuters can readily find a nearby neighbor who works at the same plant, on the same shift, and doesn’t have personal requirements to stop by the child care center or buy groceries for dinner. High Occupancy Vehicle (HOV) lanes in the USA, intended to coerce SOV commuters into car pooling, have failed to mitigate congestion. Vehicles that qualify to use the HOV lane usually contain family members and friends; thus are not bona-fide car poolers, as intended by the HOV lane restriction. The necessary dependence on the SOV results in massive congestion on urban freeways and intra-city arterial roads.

Transit in the 21st Century

Sometime within the next 15 years, the microcar will largely replace the conventional ICV for daily use, the latter now consuming inordinate road and parking lot space. Many families will still retain (or rent) an ICV van/sedan for long-range family trips, camping outings, and heavy hauls. But they will become ‘dust catchers’, due to their infrequent use.

The Car Bus will have a profound impact on urban travel in particular and quality of life in general. In 7-20 years, the microcar will become the most popular car in the industrialized world, reducing the wasteful use of the conventional-sized ICV for SOV commuting.

A typical family with two working parents and a college student will own a seldom used ICE minivan, with three hybrid/fuel cell powered microcars angle-parked within the second garage stall.

Freeway congestion will be virtually eliminated. Up to 80% of workplace and shopping mall parking lots will be redesigned, near tripling capacity. Human energy and time, now wasted in freeway traffic, will be available for more productive use.

Microcar

The conventional sized car is too large for its most used mission-commuting and neighborhood errands. But if we are to maximize the efficiency of Car Bus and parking lots in our war on congestion, a purpose-built car is in order. The minimum sized microcar was selected to be 8’ long, to match the typical width of a transporter for transverse unload/load.

Two-passenger microcars are already being built in Europe, typically 600 CC ICE-powered, 65-mph, $5K in mass production. The Mercedes SMART is a well-engineered example of the microcar.

SMART Microcar

An interesting microcar design employing composite structure and EV/hybrid power has three seats, the driver sumptuously seated in the center, providing better balance for this 800 lb. microcar.

The 3-passenger model is designed primarily as a purpose-built car for SOV commuting and neighborhood errands—what some might think of as a ‘second car’. However, families consisting of more than 2-3 people and living in apartments or high-density areas may not afford the cost or parking space of owning a microcar for each licensed driver and a standard-size car for the family. A four-passenger microcar (54" wide) is possible if the owners accept seating density equivalent to economy class in an airplane. The four-passenger model might better fit their needs.

The dilemma of which car to buy could also be solved by a growth in local auto rentals. Automation will permit reservation via phone keypad, followed by dispensing of a minivan or truck adjacent to the microcar as the renter drives into the neighborhood rental lot. Turnaround could be done in a minute.

The microcar has additional merit when automated parking garages become commonplace: the 3:1 increase in packing factor for conventional-sized cars jumps to 6-8. Park-and Ride lots thus become unnecessary in most transportation system designs employing VMT.

Autoloader

Rapid load/unload of microcars is essential to attract a maximum number of patrons: delays in excess of two minutes will make those needing only a 5-10 mile 'hitch' decide to drive the conventional way.

The loading platform (and thus the station) can be made much narrower by swiveling the pallets 45 degrees clockwise for debarking cars, then 90 degrees counter-clockwise to accept embarking cars.

A simpler scheme from that shown is to load/unload the cars by a drive on/drive off operation. In its simplest form, this requires a lateral-facing car onboard the transporter. The lateral stowage permits a very simple loading operation, the cars being either manually or remotely driven. An unload/load cycle within 10 sec. is achievable with this method, particularly if automated. Another advantage of this method is that the station footprint can more readily fit within the freeway width.

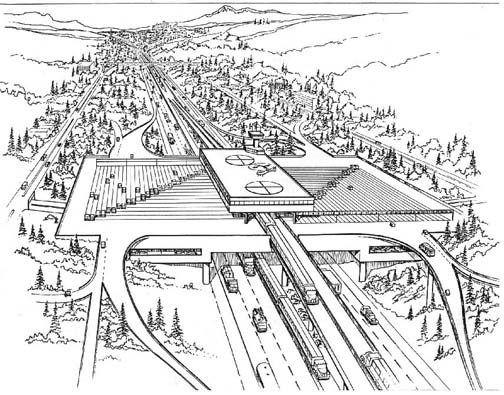

Stations

The stations for load/unload of microcars are located every 4-8 miles above the freeway. This arrangement gives the microcars access to the transporters without interfering with conventional traffic. The station shown overhangs the typical 175’ freeway width due to the autoloader design. The space beneath the main platform contains parking for the small percentage of commuters who work in the crowded central business district (CBD) where shuttles or taxis supplement walking.

Staging

A widened staging area is provided just before loading so as to permit juggling of microcars. This operation is desired so as to cluster embarking microcars to match destination stations as they proceed into a loading cycle (resembling a marching band breaking out into platoons at a football half time).

The complexity and timing of the staging operation is such that automation is desired to minimize delay and avoid the occasional snarl due to human error, if manually driven. Control data cables are laid into the roadway ramp and staging area, permitting 'hands off' remotely-controlled driving of microcars from the freeway to the loading pallets.

The scheme shown carries two forward-facing microcars abreast. It was considered a requirement that each microcar be able to embark or debark at any station independently. A 30-sec. cycle from transporter stop to start was the design target.

Transporter Design

Lateral versus forward-facing cars aboard the transporter is a major design consideration. A disadvantage of lateral-facing cars is that conventional-length cars, such as today’s ICV, cannot be accommodated in lateral loading. In the case of forward-facing conventional ICE cars, the transporter can carry only one-third as many cars as with the microcar. But being able to accommodate the longer conventional ICV may be important for gaining early acceptance of Vehicle Mass Transit (VMT). Thus, transporter designers in the early part of the 21st Century will be presented with a challenge, as the most favored commuter car evolves from a 16’ long ICV to an 8’-long EV. A modular design that could accept a variable mix of lengths and widths, without wasting valuable transporter capacity, would be ideal.

Example Transporters.

O-Bahn Bus

As the microcar becomes popular, the 92’-long O-Bahn (German) bus could be converted to a microcar transporter by replacing the body structure with a double-deck configuration: 16/deck for a favored for total of 32. The 8’ long microcars would handily fit in a lateral orientation, this also being favored for ease of unload/load, automated at10-seconds/cycle

The High Speed Surface Transportation (HSST-200) requires modification above the chassis to carry 32 microcars. The weight of the microcars, containing up to 128 passengers in the four-passenger model, is exchanged for the 158 passengers, their seats, and air conditioning equipment of the passenger-only version. Two gull wing doors on each side are required because of the bi-directional capability; that is, a transporter operating on a North-South route would retain that orientation because the front/rear ends of the 132’ long articulated transporter are identical.

Energy cost to transport 32 microcars on the HSST-200 (125-mph) is $0.23/km (based on 6-mile inter-station spacing, average 95-mph, $0.037/kwh@50kv feed). In comparison, the energy costs (from the same power utility) to drive each microcar are $0.01/mile, but at less than half the maglev transporter speed.

Central Control (CC)

The CC sub-system coordinates efficient utilization of all system elements using modern communication links, computers, and the all-important software. The location and status of every microcar and transporter is known at all times by the CC computer. The Global Position System (GPS) receiver onboard the microcar, and keyboard entries from each driver are sent to CC via digital multiplex super-imposed on the cellular phone link. Since microcar activity around stations during rush hour will resemble a beehive, a high degree of automation is desired to assure delay-free load/unload action.

Load/Unload ManagementThe central computer assigns microcars, desiring to embark, to empty (or debarking) berths in arriving transporters. This berth assigning process begins when commuters start their trip at the home driveway, entering their destination on the keyboard in the dash of the microcar.

It is not reasonable to expect clusters of microcars, based on a common destination station, to arrive simultaneously at the departure station along with their assigned transporter. Accordingly, juggling is done in the two-lane moving queue on the station approach ramps, assembling the clusters by the time they reach the loading platform. It is possible in early versions of Vehicle Mass Transit (VMT) to direct this assembly by automated commands to drivers through the cellular phone link. But remote control using Automated Highway System (AHS) technology is much preferred.

Transporter Control Sub-System

A modification of the standard headway control used for trains is required to realize the growth goal of 200’ minimum headway, required for 20 lane equivalent throughput of conventional traffic.

In order to achieve this throughput capacity, the crude century-old spacing criteria for conventional railways must be set aside, recognizing the fail-safe monitoring and control technology now available. Speed commands to individual transporters and switch commands to the guideway are CC automated functions. Back-up manual control is available for special operations. Fail-Safe operation is a design requirement. For example, a major failure in a transporter results in simultaneous emergency braking of all succeeding transporters that threaten to overrun the failed transporter.

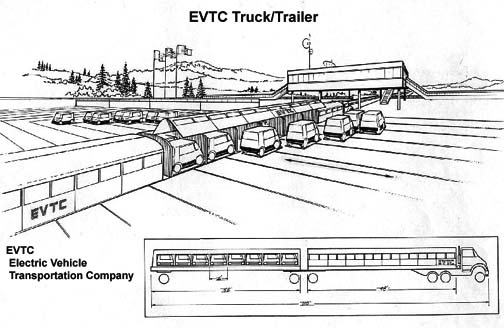

Freight Trucks

Eventually, freeways—typically having 4-6 lanes each way-- will have two automated lanes each direction: One for 250-mph maglev transporters carrying a mix of walk-on passengers; and microcars containing passengers (similar to the Chunnel Le Shuttle); and a second lane for light weight high-performance (80-mph) rubber-tired freight trucks, operating between the inside lane dedicated to maglev transporters, and the remaining 3-4 lanes carrying conventional manually-driven cars and trucks.

Demonstration Project

Since the microcars, transporters, stations, guideway, and central control are designed as an integrated system, they should not be installed piecemeal into an existing transportation system without first conducting a proof-of-concept demonstration. The purpose of the demo is to establish patron use patterns, fine-tune operating software, proof-test hardware, and gain operational experience.

Test Facility

To ensure that all the components of the system play together requires a working model, complete with station, autoloader, test track, and CC. The autoloader, automated clustering of microcars on the staging ramp, and the CC software that coordinates this activity are all critical to delay-free operation.

However, a primitive (early) system, employing a rubber-tired chassis like Autobus transporting conventional-sized cars, is more likely to gain support because of the familiar technology. Such a demo would require less system-level testing, emphasis being placed on station and autoloader design. The guideway, using existing freeways, should plan for conversion to maglev, consistent with the long-term goals to achieve the ultimate transit system.

Urban Mobility Initiative

Polls taken in most urban areas of the USA reveal that traffic congestion is the most vexing problem facing our society. However, global warming is often given more attention, possibly because the scientific community and our legislators assume that congestion is something that is a given part of a modern society, not curable.

Both issues can be addressed through the synergy of the Car Bus, in concert with the new hybrid and fuel cell powered family of cars being developed in the USA under the Program for a New Generation of Vehicles (PNGV).

An ideal way to attack these coupled problems would be via an URBAN MOBILITY INITIATIVE at the federal level. Considering that the feds spent $26B (year 1960 $) on the APOLLO man-to-moon program, it is reasonable to assume that we should be willing to allocate $30B (year 2000 $ averaged at $3B/yr over ten years) to solve our #1 societal problem.

A proposed program is outlined below, involving progressive technology. The initial proof-of-concept demonstration employs the low-tech rubber-tired Autobus, eventually evolving to the ultimate "dream" transit system using silent, smooth maglev.

DEMO 1A- Los Angeles; Santa Monica-Ontario E-W on I-10 (54 miles), manually driven Autobus transporting nine conventional-sized ICE cars. Stations located off the freeway within cloverleaves. Operational 2002.

DEMO 1B- Los Angeles; San Fernando-Irvine N-S on I-5 (60 miles). Same as Demo 1A, except ‘hands off’ automated operation on a dedicated inside lane (busway) of the freeway. Stations are located over the freeway to assure an unobstructed right of way (ROW). Operational 2004.

DEMO 2- Seattle; Lynnwood-Tacoma on I-405 (59 miles). HSST maglev truck carrying 32 8’ long FC-powered microcars. Designed for urban applications and 125-mph intercity use. Operational 2006.

DEMO 3- Houston; Galveston-Dallas on I-45 (270 miles) 500 km/h cryogenic maglev on elevated guideway over freeway medians, carrying 64 PNGV composite/FC hypercars. Operational 2010.

Demo 1A will effectively double car throughput on a five lane (each way) freeway. Demo 2 with microcars will effectively add up to 20 lanes (each way) car throughput to a typical 10-lane (total) freeway, effectively quadrupling cars/hr capacity, using existing ROW freeway footprints.

On Demo 1B, automated high performance freight trucks can be interwoven (called ‘zipping’) with the Car Bus. On Demo 2, an automated truck lane can be added alongside the barriered and shrouded at-grade guideway for HSST. This configuration has three lanes (out of five) remaining for conventional traffic.