Palleted Automated Transportation (PAT)

This is a transportation system giving dual-mode

capabilities through the use of flat cars or pallets that

take people in small buses or personal vehicles and that are

routed automatically on guideways. These guideways have

off-line stations (in common with most PRT systems) giving

the possibility of non-stop travel from many origins to many

destinations. Three illustrations of stations are available.

One is an

artist's sketch . A

second shows the layout of a typical PAT rapid transit

station. A

third shows a station that provides for both freight

and auto loading. Such systems can give very high capacities

for lightweight vehicles on small guideways so long as the

headway or spacing between vehicles can be safely kept

small.

This is a transportation system giving dual-mode

capabilities through the use of flat cars or pallets that

take people in small buses or personal vehicles and that are

routed automatically on guideways. These guideways have

off-line stations (in common with most PRT systems) giving

the possibility of non-stop travel from many origins to many

destinations. Three illustrations of stations are available.

One is an

artist's sketch . A

second shows the layout of a typical PAT rapid transit

station. A

third shows a station that provides for both freight

and auto loading. Such systems can give very high capacities

for lightweight vehicles on small guideways so long as the

headway or spacing between vehicles can be safely kept

small.

A pallet or flat-car system was chosen over one

involving dual-mode vehicles (i.e. vehicles able to travel on

the guideway and on public roads) because of safety and cost

concerns. The safety problem is obvious: vehicles used on

public roads would need rigorous inspection each time they

join the guideway. The would also need to carry guidance,

control and propulsion equipment for both forms of travel,

making them heavier, more dangerous in accidents and less

fuel-efficient in their use on the roads. It was decided that

vehicles completely captive in the system but capable of

carrying a wide variety of road vehicles and freight would

combine maximum safety with the lowest practicable cost and

fuel use.

The propulsion and control system chosen by MIT ( and

patented on Independence Day 1972, # 3.673,966, long since

expired) was to drive the pallets by synchronous

vertical-axis electric motors driving pinion gears engaging a

rack on a low left-side guiding wall. Illustrations of a

geared-screw synchronous accelerator and a

synchronous rack/pinion propulsion and control system

are provided. Not only does this system guarantee that

spacing is accurately held, but it converts motors on

vehicles going downhill into alternators, thus pumping energy

back into the system. The critical entrances and exits from

the guideway are made by the pallet engaging a right-hand

guiding wall, on which the power is supplied at an

appropriately varying frequency. A low-tech alternative

acceleration/deceleration system was a variable-pitch screw

drive by a trackside synchronous motor.

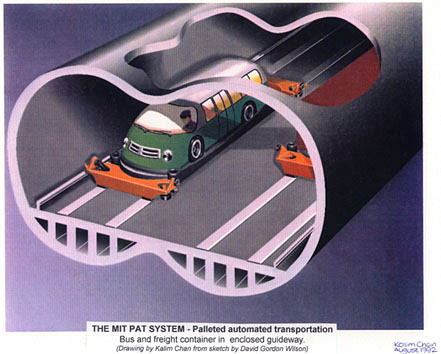

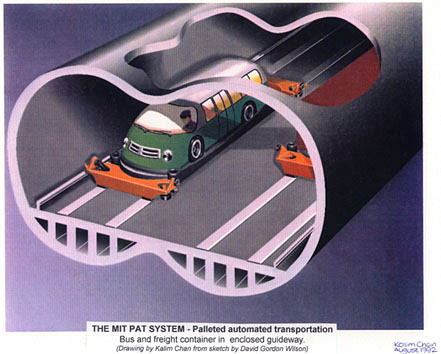

The PAT system was modeled on computers and on several

small-scale working systems. Studies of the predicted use

were made by substituting the PAT system for the Boston-area

transit system (the MBTA). The results showed large gains in

ridership and reductions in automobile and truck use. PAT was

designed to be used in dense urban areas, where the guideway

speed would be about 10 m/s, 22 mph; to extend to the suburbs

at 20 m/s, 45 mph; and to be used between cities at guideway

speeds of 40 m/s, 90 mph, perhaps located along the median of

interstate highways. The automated loading and unloading of

pallets would lead to outstanding levels of service for the

movement of both people and freight. An illustration of what

an

auto and a bus on a pallet might look like is provided

as is an

aerial view of how a PAT guideway could be integrated

with a typical freeway interchange.

The PAT group of students and faculty at MIT produced

many reports on PAT and alternative systems. Many of the

illustrations included here are borrowed from these

studies.

The above was written by Professor

David Gordon Wilson of the Massachusetts Institute of

Technology in Cambridge, Massachusetts. He also provided the

illustrations. More details can be obtained via e-mail from

him.

Last Modified: September 1, 1997

This is a transportation system giving dual-mode

capabilities through the use of flat cars or pallets that

take people in small buses or personal vehicles and that are

routed automatically on guideways. These guideways have

off-line stations (in common with most PRT systems) giving

the possibility of non-stop travel from many origins to many

destinations. Three illustrations of stations are available.

One is an

artist's sketch . A

second shows the layout of a typical PAT rapid transit

station. A

third shows a station that provides for both freight

and auto loading. Such systems can give very high capacities

for lightweight vehicles on small guideways so long as the

headway or spacing between vehicles can be safely kept

small.

This is a transportation system giving dual-mode

capabilities through the use of flat cars or pallets that

take people in small buses or personal vehicles and that are

routed automatically on guideways. These guideways have

off-line stations (in common with most PRT systems) giving

the possibility of non-stop travel from many origins to many

destinations. Three illustrations of stations are available.

One is an

artist's sketch . A

second shows the layout of a typical PAT rapid transit

station. A

third shows a station that provides for both freight

and auto loading. Such systems can give very high capacities

for lightweight vehicles on small guideways so long as the

headway or spacing between vehicles can be safely kept

small.