Integrated Transportation System

The Integrated Transportation System (InTranSys) is

a paper concept that is being developed in Colorado. It represents a major departure from

today's transportation methods but does not rely on any new and untested technological

breakthroughs. It is a unique combination of existing technologies combined to take full

advantage of the positive features of each. It is a dual-mode system in that it does not

replace the auto/truck system but supplements it in significant ways.

The Integrated Transportation System (InTranSys) is

a paper concept that is being developed in Colorado. It represents a major departure from

today's transportation methods but does not rely on any new and untested technological

breakthroughs. It is a unique combination of existing technologies combined to take full

advantage of the positive features of each. It is a dual-mode system in that it does not

replace the auto/truck system but supplements it in significant ways.

All travel on the system takes place on an interconnected network of elevated

guideways. Both urban and intercity markets could be served. Maximum speed on urban links

would be 60 mph and 150 mph would be possible on rural and intercity links. The two types

of track would be joined at suitable points by short acceleration/deceleration segments

where each vehicle would undergo a controlled speed change. These projected speeds were

selected to maximize the energy efficiency of the system and to reduce the space

requirements of the system so that it would be easier to build in urban areas.

Vehicles would be propelled by linear synchronous motors (LSM's). These devices are

similar to conventional rotary synchronous motors, like those used in electric clocks, in

that the speed of the moving component depends solely on the frequency of the alternating

current applied to the motor. They differ from clock motors, of course, in that the moving

element travels in a straight line rather than in a circle. LSM's have been produced with

efficiencies of as high as 98%, placing them among the most efficient mechanical devices

known. But of even greater importance is the fact that the constant speed of travel

automatically yields absolute control of the speed of every vehicle using the system. No

vehicle can possibly travel faster or slower than any other. Since they must always remain

in the same spatial relationship relative to one another, they can be placed very close

together. For example, at 150 mph, only about 7 inches need be allowed between consecutive

vehicles to prevent them from colliding.

This precise speed control imparts to the system an extremely high maximum capacity:

about 14,400 vehicles per hour on urban tracks and 36,000 per hour on rural sections. The

later figure is about 18 times the maximum capacity of a single freeway lane. Another

advantage of an LSM is that all motor braking is automatically regenerative. This means

that vehicles descending a steep hill or being brought to a stop feed electric power back

into the system at the same frequency as that being consumed by the system without the

need for any separate regeneration apparatus. When one combines this feature with the

inherent efficiency of the LSM and the low friction loss of steel wheels on steel rail, it

should be possible to realize a very high system energy efficiency.

In any synchronous motor, alternating current can be applied either to the moving

motor magnets or to the stationary ones. InTransSys would employ permanent ceramic magnets

on the track system and would use AC for electromagnets mounted on vehicles. The

advantages of this arrangement are: power need not be applied to the stationary units when

no vehicle is present, this resulting in even greater energy savings; and they require

virtually no maintenance over their lifetime.

In order to get high capacities, the timing of vehicles entering and network must be

controlled precisely. This would be accomplished by using computers to perform three basic

functions. First, it would find the shortest and/or quickest route through the network.

Then, it monitors all existing traffic and selects the first suitable time slot for entry.

Finally, it accelerates the vehicle with sufficient precision so that it merges smoothly

with the other traffic. These operations would be assisted by the constant speed of travel

of the vehicles on the system.

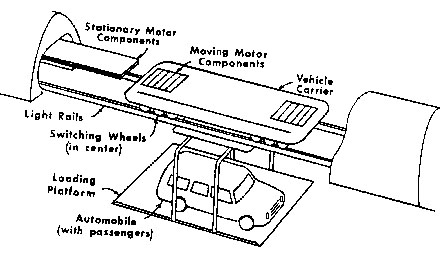

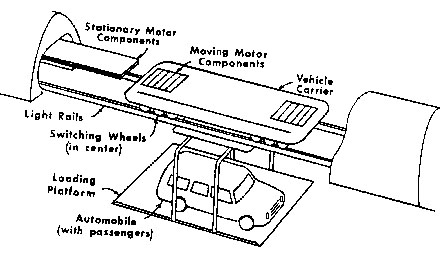

Conventional rail switches cannot be used on any system with close spacing between the

vehicles. Therefore, a new type of passive switching system has been devised which permits

the rails to remain stationary, while the direction of travel taken by each vehicle at a

switch is controlled by the shifting of special wheels mounted on the vehicle. The routing

of any vehicle requires only a series of yes-no commands describing the direction of

travel at each switch.

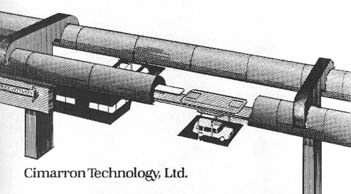

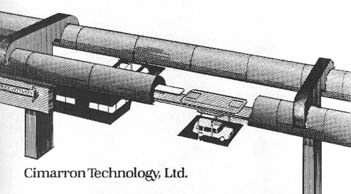

InTransSys uses tracks which are overhead to enclose the rails, motors and other

features with a continuous structure open only at the bottom. This allows the system to be

completely weatherproof. At interchanges, grade separation can be achieved simply by

varying the height of the towers supporting each track, adding little to overall

construction costs.

Each vehicle traveling along the track must be equipped with some rather sophisticated

components, such as the moving parts of the LIM, steel wheels mounted on high-speed

bearings, switching wheels, a small on-board computer and other items. All such items are

part of special devices known as vehicle carriers. A diagram of one of these carriers is

shown below. Virtually any kind of private passenger vehicle can use the system without

extensive modification to the vehicle as the car rests on a platform to which it is locked

by a suitable clamping device. This is the platform that is attached to the vehicle

carrier and travels suspended beneath it.

Loading onto this system takes place only at

stations. In order to travel on the system, a motorist drives from his home or any other

location to the nearest station. He then selects one of several loading stalls, drives his

car onto the platform and attaches a simple electrical connection between the platform and

his car. This connection allows the system to identify his car, permits attachment of the

car to the platform, facilitates billing and prevents unauthorized use of the car. The

driver dials the number of the station he wants to reach and his role in making the trip

is finished until that station is reached. The system is being designed to also serve

small buses and cargo containers. An observer of a typical line would see several

different types of loads being carried by the system.

Loading onto this system takes place only at

stations. In order to travel on the system, a motorist drives from his home or any other

location to the nearest station. He then selects one of several loading stalls, drives his

car onto the platform and attaches a simple electrical connection between the platform and

his car. This connection allows the system to identify his car, permits attachment of the

car to the platform, facilitates billing and prevents unauthorized use of the car. The

driver dials the number of the station he wants to reach and his role in making the trip

is finished until that station is reached. The system is being designed to also serve

small buses and cargo containers. An observer of a typical line would see several

different types of loads being carried by the system.

The major advantage that InTranSys would enjoy over other systems lies in the very low

operation and maintenance costs, plus the extremely high energy efficiency it could

attain. Well over half of the long-term system costs would come from construction of the

guideways, stations and other facilities.

A document of about 150 pages that describes the InTranSys concept in more detail is

available as is a 30-minute video that uses animated computer graphics to describe its

attributes and concepts. For more details on this technology, visit the InTransSys FAQ and the InTransSys website.

Contact information: Dr. James R. Guadagno, General Partner, Cimarron Technology,

Ltd., P.O. Box 789, Paonia, Colorado 81428; phone/fax: 970-527-4563. E-mail: cimarron@co.tds.net

HOME

Last modified: December 07, 1999

The Integrated Transportation System (InTranSys) is

a paper concept that is being developed in Colorado. It represents a major departure from

today's transportation methods but does not rely on any new and untested technological

breakthroughs. It is a unique combination of existing technologies combined to take full

advantage of the positive features of each. It is a dual-mode system in that it does not

replace the auto/truck system but supplements it in significant ways.

The Integrated Transportation System (InTranSys) is

a paper concept that is being developed in Colorado. It represents a major departure from

today's transportation methods but does not rely on any new and untested technological

breakthroughs. It is a unique combination of existing technologies combined to take full

advantage of the positive features of each. It is a dual-mode system in that it does not

replace the auto/truck system but supplements it in significant ways. Loading onto this system takes place only at

stations. In order to travel on the system, a motorist drives from his home or any other

location to the nearest station. He then selects one of several loading stalls, drives his

car onto the platform and attaches a simple electrical connection between the platform and

his car. This connection allows the system to identify his car, permits attachment of the

car to the platform, facilitates billing and prevents unauthorized use of the car. The

driver dials the number of the station he wants to reach and his role in making the trip

is finished until that station is reached. The system is being designed to also serve

small buses and cargo containers. An observer of a typical line would see several

different types of loads being carried by the system.

Loading onto this system takes place only at

stations. In order to travel on the system, a motorist drives from his home or any other

location to the nearest station. He then selects one of several loading stalls, drives his

car onto the platform and attaches a simple electrical connection between the platform and

his car. This connection allows the system to identify his car, permits attachment of the

car to the platform, facilitates billing and prevents unauthorized use of the car. The

driver dials the number of the station he wants to reach and his role in making the trip

is finished until that station is reached. The system is being designed to also serve

small buses and cargo containers. An observer of a typical line would see several

different types of loads being carried by the system.