CONCLUSIONS

In this project, seven bio-acids, pH and ethanol were measured quantitatively in

fermenting coffee samples at three pH ranges corresponding to (1) optimum

fermentation completion (mucilage just liquified) and (2 and 3) two over-fermented ranges

corresponding to approximately 0.33 pH unit and 1.5 hours past

optimum to 0.7 pH unit and 4 hours past optimum, respectively. From the quantified bio-acid and ethanol concentrations

in these ranges the following conclusions can be drawn:

•The bio-acids glacturonic, formic, malic, acetic, citric and propionic are found not to

vary during the conditions of over-fermentation.

•Both lactic acid and ethanol increase in concentration with statistical significance

(one-tailed t test) between ranges 1 and 2 and 1 and 3. Both lactic acid and ethanol concentrations

approximately quadrupled during the period of over-fermentation.

•The use of pH as an indicator of over-fermentaion is justified. The other species, namely, ethanol and

lactic acid, track with pH and have been found to be indicative of over-fermentation.8,9

The findings of this research will lead to a better understanding of the

coffee mucilage fermentation process. This knowledge can then be

applied to generate coffee improvement methods beneficial to family

coffee farms. Results from this and

future research may lead to new, inexpensive techniques that can be utilized

and applied by impoverished coffee farmers in Nicaragua and other poverty-stricken countries

impacted by the coffee crisis.

HPLC and test strip

analysis of bio-acids produced in fermented coffee mucilage on

small farms in Nicaragua

Jackels, S.*, Edquist, B.*, Pham, T.*, Jackels, C.**,

Rivas, R.***, and Vallejos, C.***

*Seattle University, Seattle WA, **University of

Washington Bothell, Bothell WA, ***University of Central America Managua,

Managua NI

RESULTS

Acids determined by HPLC in

fermenting coffee samples:

Table 1. Order of elution of organic acids.

Since lactic and

ascorbic acids eluted in the same peak, these acids were

determined by the Reflectoquant test strip method. Ethanol was determined by Reflectoquant test

strip.

Prior to initiation

of fermentation, the following concentrations were found in freshly depulped

coffee muclilage.

Table 2. Initial Concentrations

prior to fermentation.

As shown in the

Table 3 below, for 25 samples, galacturonic, formic, malic, acetic, citric

and propionic acids were found not to vary during the course of fermentation.7

Table 3. Average concentrations

of non-statistically varying acids.

As shown in Table

4, next column, for 25 samples, average lactic acid and ethanol

concentrations were found to increase during the course of fermentation

from range 1 to range 3.

Table 4. (See next column, above) Average concentrations and changes of lactic acid and ethanol

(mg/L) during pH ranges of fermentation. aReported as: mean (standard deviation, number of batches); bReported as: change in mean (one-tailed p-value from

t-test).

ABSTRACT

Small-holder coffee farmers in developing countries like

Nicaragua are seeking reliable

methods to produce better coffee and the information and tools needed to enter specialty coffee markets like Fair Trade and

Organic. The goal of this research is to understand the changes taking place

during a critical step in coffee

production on the farm: the fermentation step that uses a natural process to break down coffee mucilage fruit that clings to the

coffee beans. This paper reports the results of a field study conducted during

the 2005-06 Nicaraguan coffee

harvest in order to investigate the relationship between scientific control of the coffee fermentation process and the quality of

the resulting roasted coffee. First, small-scale, well-controlled

laboratory fermentation was carried out

on twelve different daily batches of coffee at the farm La Canavalia in Matagalpa, Nicaragua.

With otherwise identical treatment, fermentation of the small samples was halted by washing when the pH of the

fermenting mass decreased from

a starting pH of 5.8 to approximately 4.6, 4.3, or 3.9. Samples of coffee with mucilage were reserved and frozen for

laboratory analysis. Bio-acids were separated and quantified by HPLC (for formic,

proprionic, citric, malic, acetic,

and glacturonic) or Merck Reflectoquant test strips (for ascorbic and lactic). Results of this study, including

correlation between the final fermentation

pH and bio-acid profiles, will be presented.

This project was supported

by a NSF Discovery Corps Senior Fellowship (CHE-0512867).

INTRODUCTION

With coffee prices

reaching the lowest inflation-adjusted prices in 100 years in

2001, the impact remains considerable among the poverty-stricken

coffee producers in developing countries.1 Nicaragua, the second poorest country in the

Western

hemisphere, has lost roughly 122,000 jobs to the crisis and has experienced

a notable impact on family farms.2 One solution to the crisis is to aid family

farms with development programs.

Cooperative groups of farmers are working toward organic and

fair-trade certifications and are using inexpensive methods to farm and produce

better coffee for specialty markets in developed countries.

Though there are several

steps in the processing of coffee, the fermentation step (step 6, Fig. 1) is the step of focus for this research. Over-fermentation and under-fermentation of coffee mucilage alters the

beverage’s quality by creating an unpleasant taste and smell.3 Currently, most

Nicaraguan coffee producers determine the completion time for fermentation of coffee

mucilage manually. This is problematic since the

fermenting mucilage must be checked on periodically given that the amount of time

needed to ferment has many variables and is different each day.

Previously, our

research has connected pH of coffee mucilage to stages of fermentation. 4 The pH of coffee mucilage at different

points of fermentation (under, over and optimal fermentation) was

measured and lead to the findings that coffee is optimally fermented around a

pH of 4.6 and as coffee mucilage becomes more fermented, the pH decreases.

METHODS

During the harvest

of December 2005, small-scale, well-controlled fermentation was carried out on

eleven daily batches of coffee processed on the farm La Canavalia in Matagalpa, Nicaragua. Each field experiment consisted of six buckets derived from a

common batch of coffee. The fermentation was

terminated and samples were collected at the time of washing which

was controlled such that the pH was in the range 4.5 – 4.8 (range 1), 4.1 –

4.4 (range 2), or 3.6 – 4.0 (range 3).

Fermentation was “complete,” meaning that the mucilage was

liquified, in range 1 so that ranges 2 and 3 were over-fermented

by 1.5 to 4 hours. Samples were collected and frozen after

being field analyzed for pH, glucose, lactic acid and ethanol.

Subsequently, in

the Seattle University laboratory, coffee mucilage samples were

prepared by thawing sample coffee beans with attached mucilage. 30 g of coffee sample were mixed with 50 mL of

purified water. The mixture was stirred for forty-five

minutes with the magnetic stir bar and 4.5mL aliquots of the

solution were taken and centrifuged (5 min at 10,000 g). The supernatant was filtered twice through 0.45 μm

micrometer filters. Finally, 1400

μl of the resulting liquid was then placed in a vial containing a 200 μL of

pyrazinecarboxylic acid standard solution (0.05mg/mL) for analysis

by HPLC (Agilent 1100 series instrument). The mobile phase was 0.5 %

aqueous ammonium phosphate at pH 2.8. The flow rate was 0.8 mL/min.with an Alltech

Prevail column (5 μm particle size, 4.6 mm x 150 mm size) and detection in the ultraviolet (Spectraphysics Model

8450) at 260 nm.

REFERENCES

1 Oxfam International. 2003. Mugged: Poverty in your Coffee

Cup. Oxford, U.K.: Oxfam Publishing Nov. 2003.

58P.

2 International Coffee Organization. 2003. Impact of the coffee crisis on poverty in producing countries. London:

International Coffee Organization.

International Coffee Council document 89-5. 10 p. Available: http://www.ico.org/documents/icc89-5r1e.pdf.

3 Lopez, C.I.; Bautista, E.; Moreno, E.; Dentan, E. ASIC 1989, 13, 373-384.

4 Jackels, S.; Jackels, C. J. of Food Science. 2005, 70, 321-325.

5 Jackels, C.; Jackels, S.; Kleven, S.; Fraser-Dauphinne, S.;

Vallejos, C. Proceedings of the 21st ASIC meeting. 2006, 434-443.

7 Rivas, R. Undergraduate Research Thesis, University of

Central America Managua, 2006.

8 Avallone, S.; Guiraud, J.P.; Guyot, B.; Olguin, E.;

Brillouet, J.M. J. of Agricultural and Food Chemistry. 2001, 49, 5556-5559.

9 Avallone, S.; Brillouet, J.M.; Guyot, B.; Olguin, E.;

Guiraud, J.P. International J. of

Food Science and Technology 2002, 37, 191-198.

Background Image from Flickr:

http://flickr.com/photos/tonx/145685020/

RESEARCH QUESTION

What is the

relationship between the pH and the concentration of bio-acids in coffee mucilage

sampled at different stages of fermentation? Hpothesis: lactic acid is responsible for the drop

in pH at the time of completion.

5. Pulped coffee emerging

from the cherry pulping machine

6. Pulped coffee in a cement tank with a drain

(no water added) for natural fermentation

7. Washing the mucilage

from the fermented coffee

8. Drying and sorting

defective coffee beans

9. Final drying stage,

under the sun

10. Coffee stored in warehouse until sold

Figure 1. Steps in coffee process on the farm Nicaragua.

1. Harvesting of ripe coffee cherries

2. Sorting picked cherries to remove unripe cherries

3. Coffee cherries washed and selected by density

4. Coffee cherries mechanically pulped in the wet mill building

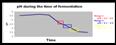

Optimal fermentation is the point when the mucilage is liquifed so that it can be

washed off the beans. Previous field research5 established the variation of pH during the

coffee fermentation period as shown in Fig. 2.

These studies established that the coffee mucilage became liquified in pH range 1

(4.5 – 4.8) and in ranges 2 and 3 the coffee was over-fermented

resulting in a decrease in coffee quality observed in the resulting roasted

coffee in the cup.5

The goal of the present research is to understand the changes taking place during the

natural fermentation step in coffee processing.

Toward this end, we used HPLC and enzyme- based test strips to

measure bio-acid concentrations in controlled experiments on fermenting

coffee.

The HPLC data were collected with the Peak SimpleTM system and were quantified

by peak integration in comparison with calibration curves of the

pure acids. Statistical analysis of

the results was carried out with Excel.

These solutions were also tested for lactic and ascorbic acid concentrations and pH

using the reflectoquant system.6

Figure 2. Curve showing the

variation of pH during coffee fermentation.

ACKNOWLEDGEMENTS

This project was supported by a NSF Discovery Corps Senior

Fellowship (CHE-0512867). Edquist and

Pham acknowledge summer research support through a Merck/AAAS grant. The authors thank Catholic Relief

Services/Nicaragua and the cooperative ADDAC for access to the farm and

use of coffee during processing.

15.1

Standard

(pyrazine carboxylic

acid)

11.4

Propionic

6.1

Citric

4.5

Acetic

3.9

Lactic and

Ascorbic

3.3

Malic

2.7

Formic

2.1

min.

Galacturonic

HPLC elution time

Organic

Acid

10

130

Propionic

30

250

Citric

80

320

Acetic

60

220

Malic

190

340

Formic

320

10,600

Galacturonic

Standard

Deviation

Average

Concentration (mg/L)

Acid

377

(291, 9)

117

(26, 9)

3.88

(.16, 9)

Range

3a

110

(.044)

41

(.009)

-0.33

(.0005)

Change

(1→2)b

266

(.034)

88

(.024)

-0.70

(2.9 x 10-6)

Change

(1→3)b

221

(129, 11)

70

(31, 11)

4.25

(.14, 11)

Range

2a

111

(45, 5)

29

(17, 5)

4.58

(.18, 5)

Range

1a

Ethanol

Lactic

Acid

pH

Table

4.

515

2,150

mg/L

Glucose

2.9

4.9

mg/L

Lactic

Acid

8.0

16.6

mg/L

Ethanol

0.18

5.92

pH

Std. Dev.

Average

Concentration