I study our individual and collective struggle to understand computing and harness it for play, power, equity, and justice.

I work with outstanding students and vibrant communities on this work, publishing it in Computing Education, Human-Computer Interaction, and Software Engineering communities, and then blogging, presenting, teaching, synthesizing, and applying it in the world.

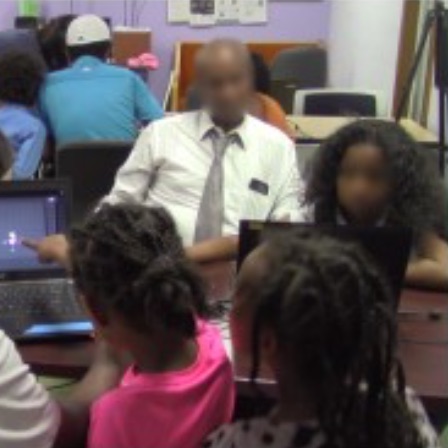

My active research projects are largely shaped by the postdocs and doctoral students in my lab and my active grants. My recent publications are a good guide to my current focus. I'm currently focused on justice-centered computing education. This includes more equitable programmable media (particularly 💬️ Wordplay, an accessible, multilingual educational programming language for creating interactive typography), as well as equitable, justice-centered secondary CS teacher education, including pathways and community.

I'm interested in any scholarly or community activity that advances liberation in computing education (e.g., uniting equitable pathways to CS education in the Pacific Northwest through CS for All Washington and PNW CS Teach and broadening scholarly discourse by editing ACM TOCE and building infrastructure to sustain peer review through Reciprocal Reviews.)

Want to do research with me? Read about my lab, and join us in creating a more equitable future of computing that includes everyone.

Discoveries 🔗

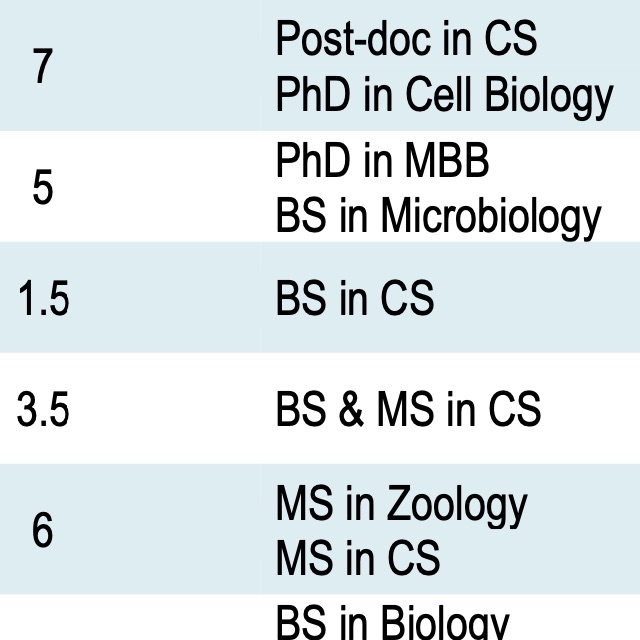

My lab and I have discovered many things since I started doing research in 1999. Here are some of the highlights from our work. How I describe these is always evolving as we learn more.

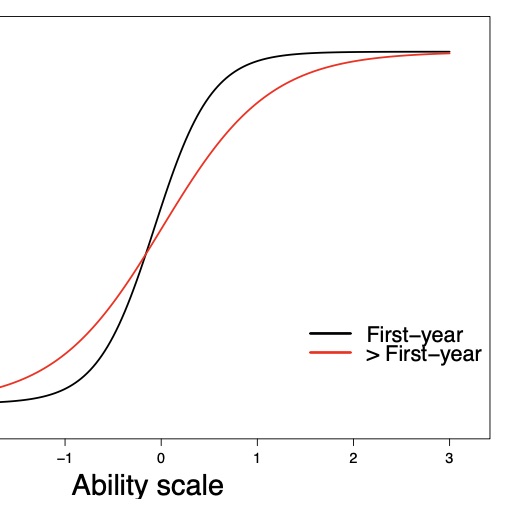

Techniques from psychometrics can help, but they are far from usable by everyday CS teachers.

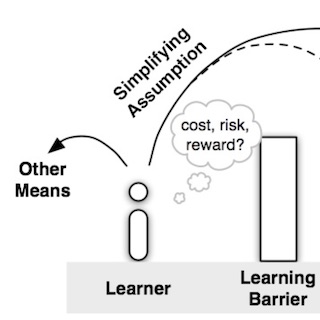

Most learners don't want to be that deliberate about their process, favoring less effective trial and error strategies. But framing it as aunthetic practice can help.

Tools can help, but even more so, using data and domains that people understand is even better.

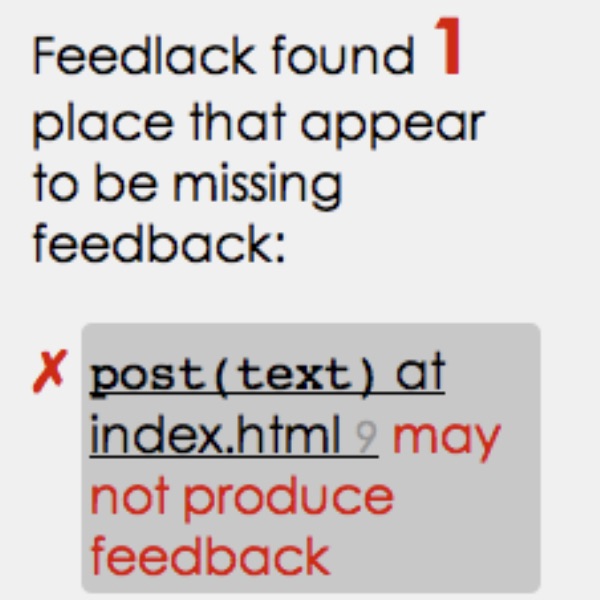

Programming is hard for many reasons, but my work showed that it is also hard because tools, APIs, and IDEs make information about program behavior particulary difficulty to find.

This is because writing skills are dependent on reading skills. Unfortunately, learning to read code correctly can be boring.

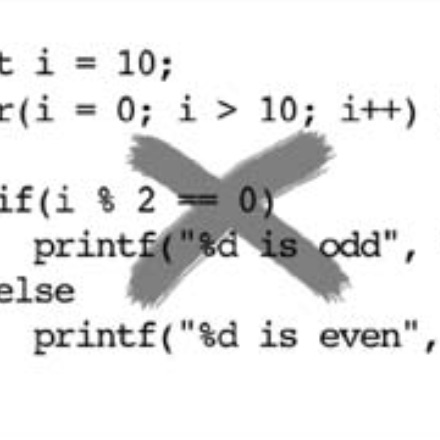

Compiler feedback is usually impersonal and mean; we found that being nicer has powerful impacts on learners' attention, compelling them to pay attention to valuable direct instruction.

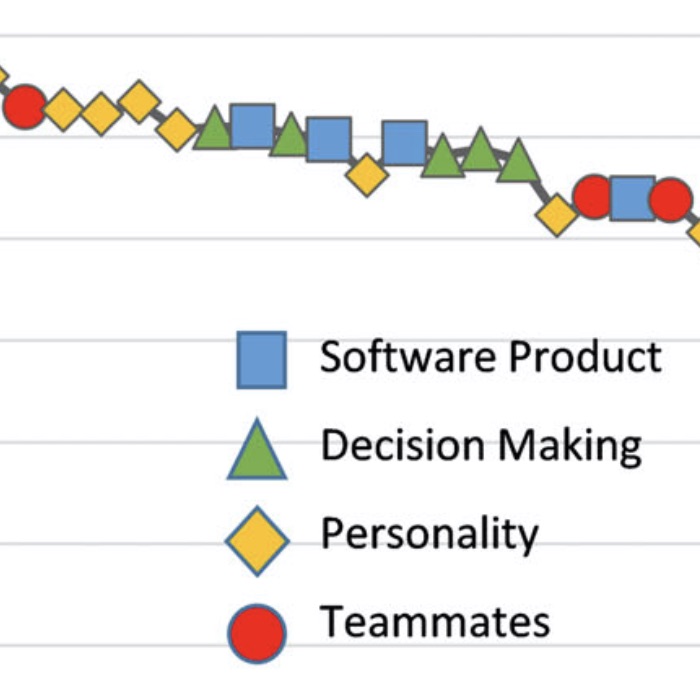

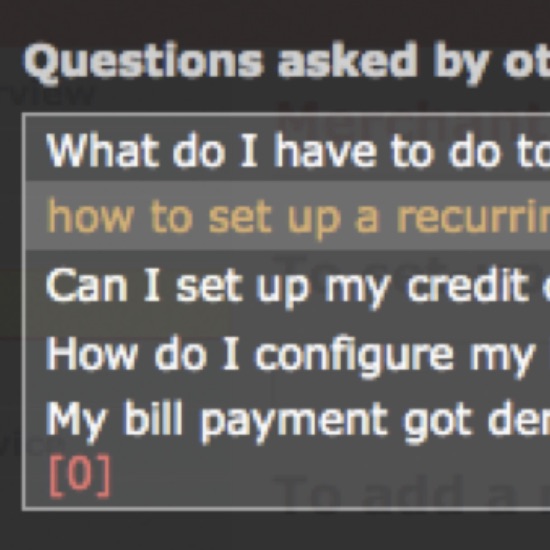

Through a series of studies, I unconvered the many ways that developers depend on information from people and systems to make engineering decisions, and how some of the most crucial information is hard or impossible to find.

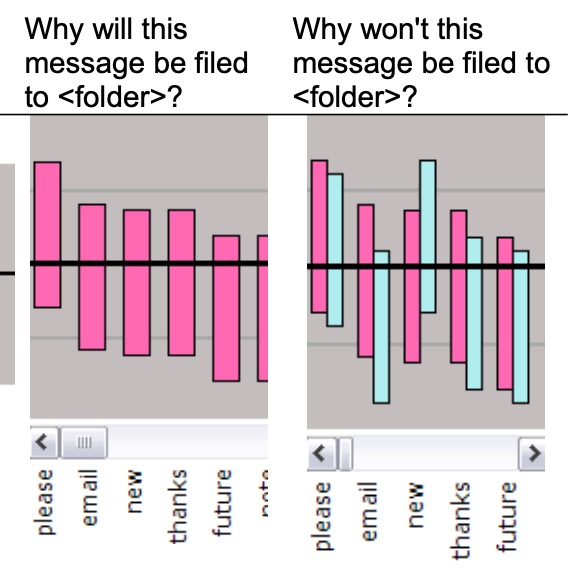

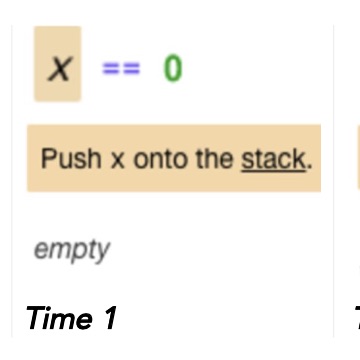

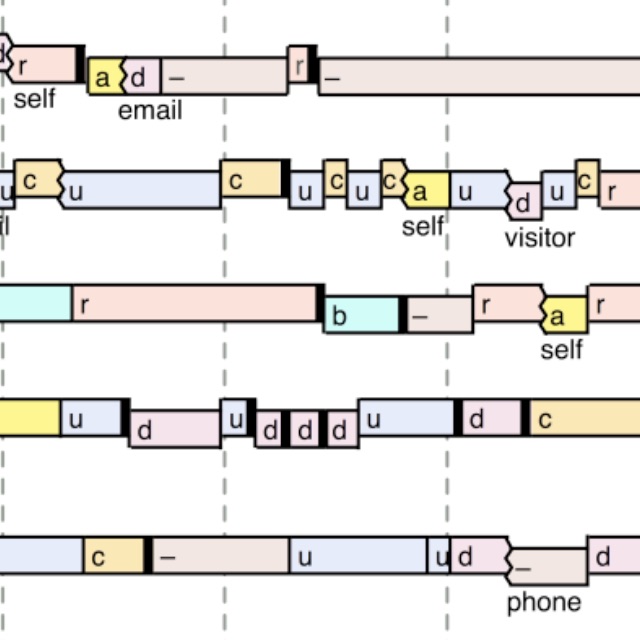

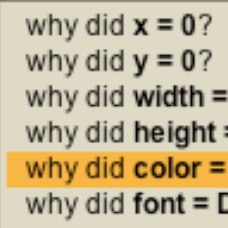

I invented tools and algorithms for deriving 'why' and 'why not' questions from programs and automatically answering those questions, helping people efficiently and interactively debug the root causes of program failures.

Many defects in dynamically typed programs can be found by operationalizing simple observations about how people write code, often forgetting to close the loop that statically typed programs can easily point out.

verificationtools 🖥️ demo {} code 📄papers

The seeminly technical context of bug reports are where large communities of users and small teams of developers engage in power struggles about what software should and shouldn't do.

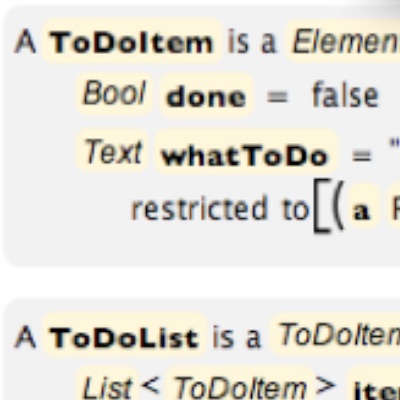

The structured editors of the 1980's were hard to build and use; I invented ways of making both easier by viewing programs as user interfaces, not documents.

Much of my work during my dissertation examined where software failures come from; cognitive slips interact with the large state space that people create when programming to generate defects that are hard to localize.

To the extent possible under law,

Amy J. Ko

has waived all copyright and related or neighboring rights to the design

and implementation of

Amy's faculty site. This work is

published from the

United States. See this site's GitHub repository to view source and provide feedback.

To the extent possible under law,

Amy J. Ko

has waived all copyright and related or neighboring rights to the design

and implementation of

Amy's faculty site. This work is

published from the

United States. See this site's GitHub repository to view source and provide feedback.